en

17

5.2

Basic systems and hydraulic variants

System

In addition to the pre-confi gured schemes 881 and 882, the controller is pre-pro-

grammed for 7 basic solar systems. The selection depends on the number of heat

sources (collector fi elds) and heat sinks (stores, pool). Factory setting is system 1.

The selection of the basic solar system is one of the most important adjustments

and is thus requested already in the commissioning menu.

First, the basic system is adjusted by means of the number of stores and collectors

fi elds, then the hydraulic variant.

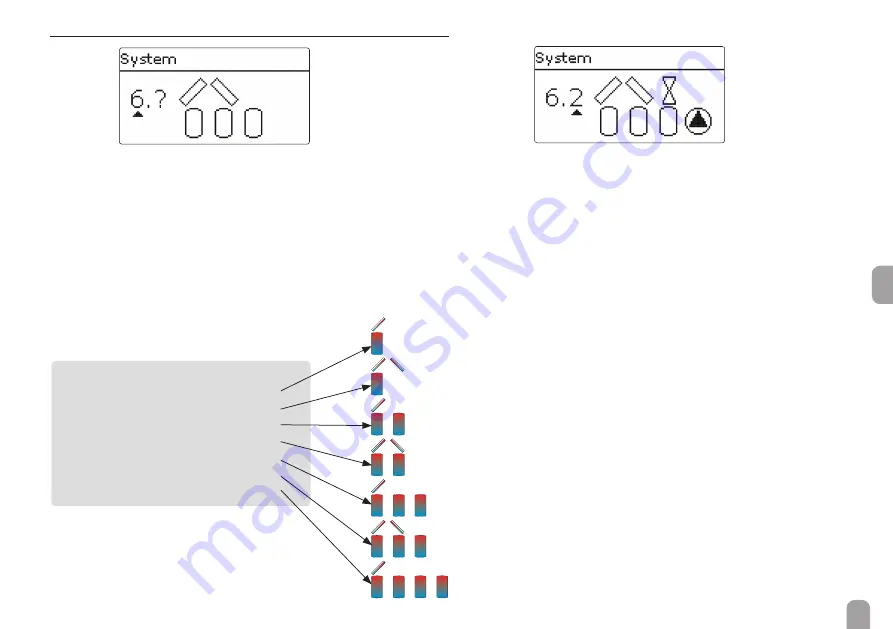

The selected system is visualised by the corresponding number of store and collec-

tor symbols. The fi gure to the left shows system 6 which consists of 3 stores and 2

collector fi elds (“east- / west collectors”).

A solar system with store charging in layers is

implemented as a 2-store system (store top =

store 1; store bottom = store 2).

System 0: no solar system

System 1: 1 collector fi eld

- 1 store

System 2: east- / west collectors - 1 store

System 3: 1 collector fi eld

- 2 stores

System 4: east- / west collectors - 2 stores

System 5: 1 collector fi eld

- 3 stores

System 6: east- / west collectors - 3 stores

System 7: 1 collector fi eld

- 4 stores

Variant

The hydraulic variant refers to the different actuators that are to be controlled.

They are visualised on the display by means of symbols, when the variant is select-

ed. The upper symbol indicates the actuator belonging to the collector fi elds, the

lower one the actuators belonging to the stores.

The exemplary fi gure shows the display indicated when system 6, variant 2 has

been selected. In this case, each collector fi eld has a 2-port valve, the stores are

loaded by means of pump logic.

For each variant, the controller allocates the corresponding relays and sensors. The

allocations of all combinations are shown in chap. 5.3.

Summary of Contents for SC5.14

Page 78: ...en 78 ...

Page 79: ...en 79 ...