EN

158

EN

159

Operation

Warning!

Always wear eye protec-

tion with side shields. Failure to do

so could result in objects being thrown into

your eyes and other possible serious inju-

ries.

Warning!

This equipment incorpo-

rates parts, that tend to produce

arcs or sparks. Do not use in explosive at-

mosphere.

Warning!

Never exceed the pres-

sure rating of the attached tool as

recommended by the manufacturer. When

using the compressor as an inflation de-

vice, always follow the maximum inflation

guidelines stated by the manufacturer of

the item being inflated.

Start up

- Ensure On/Off switch

1

is pushed in to posi-

tion O (OFF).

- Close pressure regulator

clockwise.

- Connect compressor to a suitable outlet

(see technical data). Use a residual current

device (RCD) protected outlet.

- Connect the compressed-air hose and a

suitable tool following section “Draw output

pressure” on previous page and tool manual

(e.g. some tools need to be connected to the

hose after power up.)

- Pull the On/Off switch

1

to position 1 (ON).

- Set the pressure regulator

to the minimum

pressure suitable for your tool or inflatable

item.

NOTE: When the appliance is on, the air com-

pressor will automatically run, as long as the

tank air pressure is below the preset pressure

limit. It will shut off when the max pressure is

reached.

Start up after overload cut-off

- Ensure On/Off switch

1

is pushed in to po-

sition O (OFF) and let the compressor cool

down entirely.

- Press the overload switch

.

- Proceed with a regular start up.

Shut off

- Push down the On/Off switch

to position

O (OFF).

- Unplug the compressor.

- Release output pressure by fully rotating the

pressure regulator

counterclockwise.

- Release tank pressure by rotating the un-

loading nut of the safety valve

11

and pull-

ing the valve rod

until no more air escapes.

Re-tighten nut.

- Drain the tank.

Transport and storage

Warning!

Never transport, store, or

dispose of the compressor while un-

der pressure.

- Drain the tank at the condensation drain

valve

12

.

- Disconnect the coiled hose from the com-

pressor before transport or storage.

- Lift the appliance only by its transport han-

dles

2

.

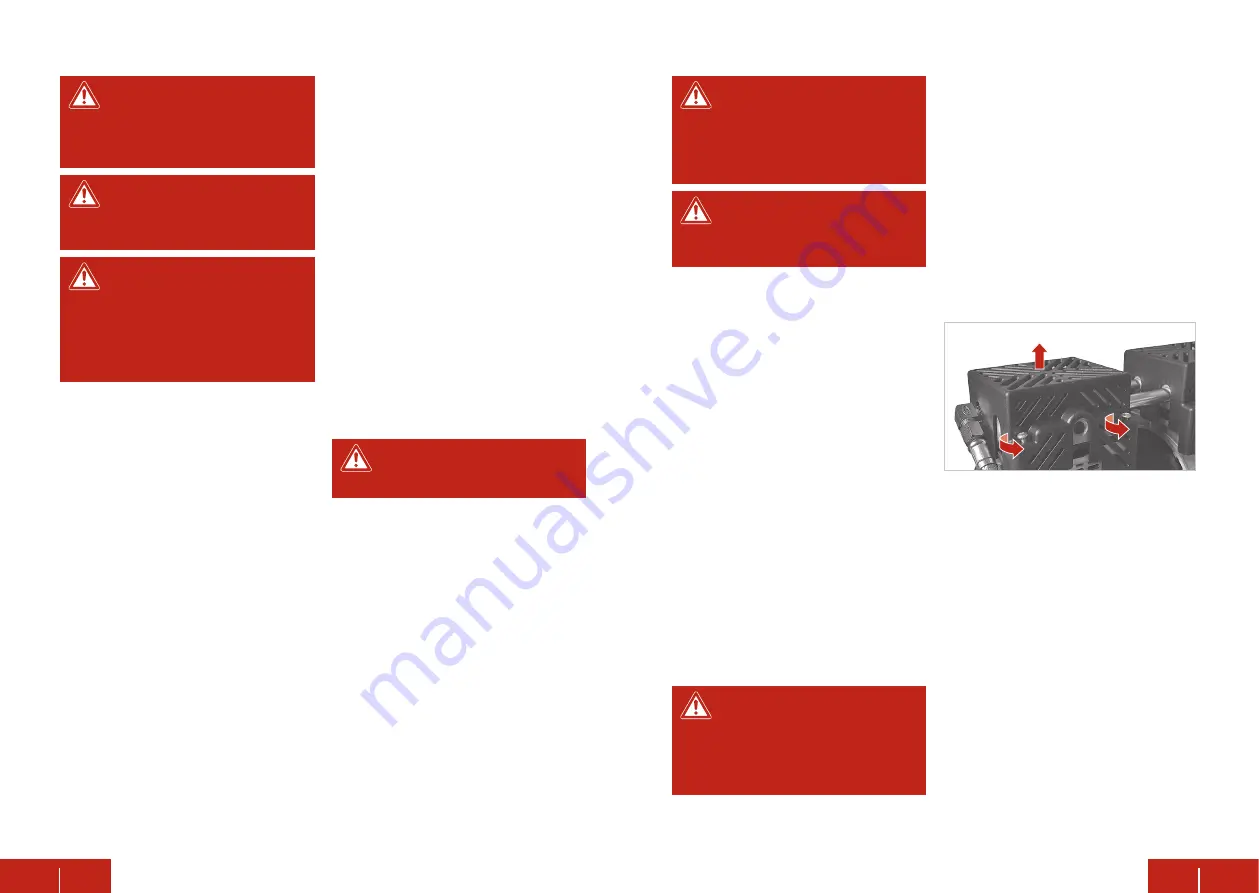

- Only transport and store the compressor in

upright position. Do not tilt more than 10°:

- Store in a dry and clean place. Lock away

from children.

Care & Maintenance

Danger!

Do not disassemble safety

relief valve or pressure regulator. Do

not open drain valves with air in tank. Bleed

tank. Failure to depressurize tank before

disassembling could result in explosion

and/or serious personal injury.

Warning!

Before performing any

work on the tool, unplug the power

supply cord. Let the appliance cool down.

Burn hazard!

-Wear safety glasses to protect your eyes

whilst cleaning and maintenance.

-

Before work:

Check safety valve

to en-

sure correct operation.

-

After work:

Drain moisture from tank at the

condensation drain valve

12

to prevent tank

corrosion.

-

Weekly:

Check for obvious defects and/or

damaged components.

-

Monthly:

Clean the air filter

-

Monthly:

Check all fixings. These could be-

come loose with time due to vibration.

-

Monthly:

Inspect the hose: The most used

part is the hose. If the hose is worn, it must

be replaced immediately.

-Have any worn or damaged parts replaced at

your local HORNBACH store.

-Always keep the machine clean, dry and free

of oil or grease.

-If the body of the machine needs cleaning,

wipe it with a brush or a soft damp cloth. A

mild detergent can be used but nothing like

alcohol, petrol or other cleaning agent.

-Never use caustic agents to clean plastic

parts.

-Regularly clean the cooling ribs. For this

purpose unscrew and remove the coverings.

Fasten the coverings after cleaning the cool-

ing ribs.

Replacement Parts

Warning!

Replacement parts must

conform with the requirements

specified by the manufacturer. Therefore

use original replacement parts only or

spare parts authorised by the manufactur-

er.

In case of service requests or spare parts,

please contact your local HORNBACH store or

write an email to: [email protected]