20

PHKS 1350 A1

GB

MT

WARNING!

►

The arrow on the saw blade must corre-

spond to the arrow showing the direction of

rotation (running direction shown on the

device).

■

Ensure that the saw blade is suitable for the

rotational speed of the tool.

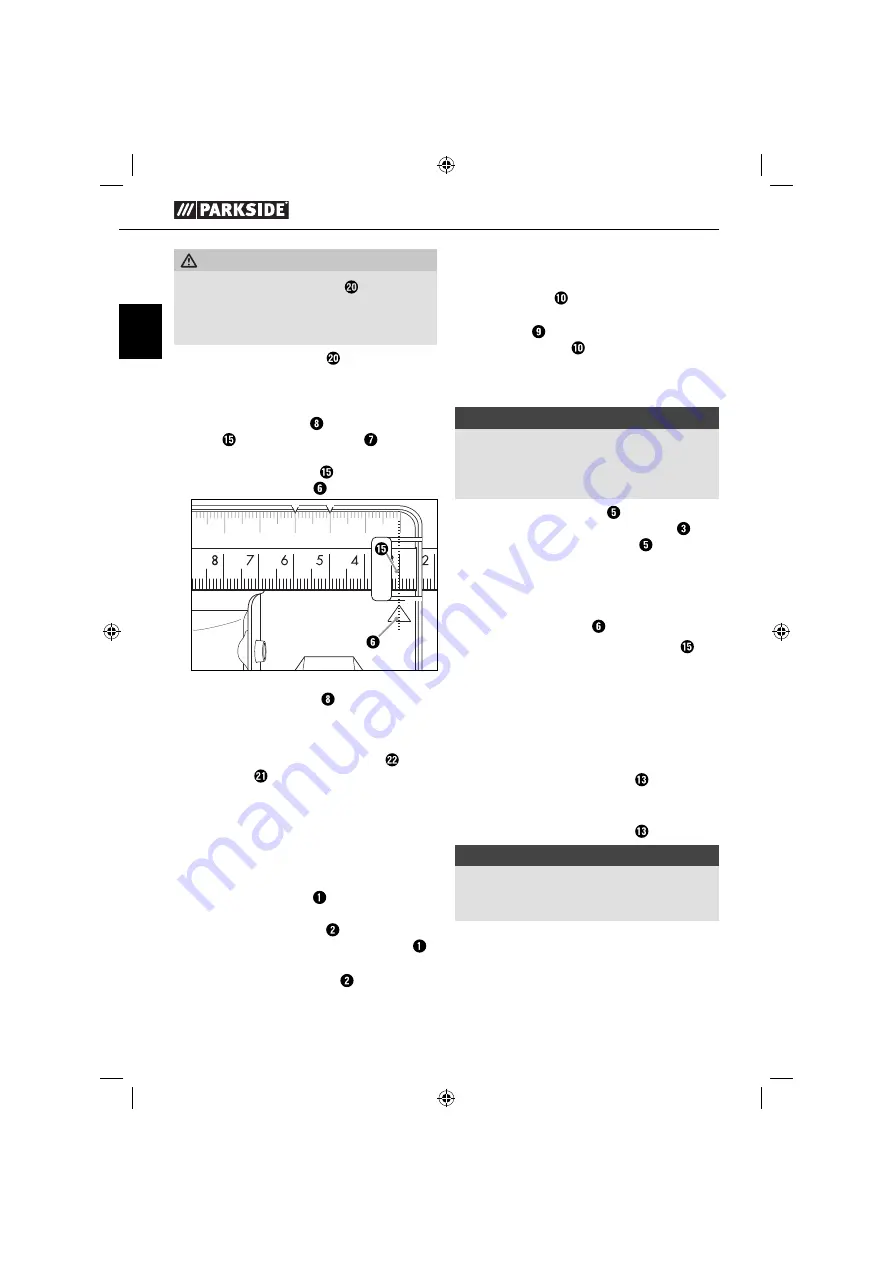

Mounting/setting the guide fence

♦

Loosen the wing screw and insert the guide

fence into the guide fence slot .

♦

Set the desired cut width with the help of the

scale on the guide fence and the marking

arrow in the base plate (see also Fig. B).

0

45

45

Fig. B: Cutting width 3 cm

♦

Retighten the wing screw .

Connecting the sawdust extraction

appliance

♦

Attach the adapter for dust extraction to the

chip ejector .

♦

Connect an approved dust and chip extraction

device.

Operation

Switching on and off

Switching on:

♦

Push the safety lock-out to the left or right

and keep it pressed.

♦

Press the ON/OFF switch . Once the saw is

running you can release the safety lock-out .

Switching off :

♦

Release the ON/OFF switch .

Setting the cutting angle

You can select the cutting angle with the help of the

cutting angle scale .

■

Release the wing screw on the cutting angle

preselector , set the desired angle on the

cutting angle scale and then re-tighten the

wing screw.

Setting the cutting depth

NOTE

►

We generally recommend setting the cutting

depth to approx. 3 mm more than the thickness

of the material. This ensures that you achieve

a clean cut.

♦

Release the locking screw , set the desired

cutting depth on the cutting depth scale and

then re-tighten the locking screw .

Working with the circular saw

1. Switch on the device – as described in "Switching

on and off " – and then place it with the front

edge of the base plate on the material.

2. Align the machine using the guide fence or

by using a marked line.

3. Hold the machine in both hands using the

handles and saw by exerting an even pressure.

Switching the laser on and off

Switching on:

♦

Press the ON/OFF switch laser .

Switching off :

♦

Press the ON/OFF switch laser .

NOTE

►

If the batteries are spent, replace them with

two new 1.5 V alkaline button cells (type

AG 13/LR 44, e.g. GPA 76) .

IB_36453_PHKS1350A1_LB5.indb 20

IB_36453_PHKS1350A1_LB5.indb 20

28.04.14 08:36

28.04.14 08:36