62

MSC4000 - MSC15000 USER MANUAL

5. Routine Maintenance

This section covers the various components that require periodic maintenance and/or replacement.

Coalescing Filter Element

The coalescing filter element should be check Bi-Annually.

The filter differential can be viewed on the controller HMI. If it is determined that there is a high pressure drop across

the machine, remove the filter element from the machine and inspect it. If the filter is dirty, replace it. Ensure that air

pressure is removed from the machine prior to removing the filter element.

The coalescing element should be changed annually. To change the filter element:

• Ensure that air pressure is removed from the machine!!

• Remove the bolts that secure the filter housing cover.

• Remove the wing nut that secures the filter cap to the element.

• Remove the filter cap.

• Remove the existing element from the housing.

• Install the replacement element.

• Reinstall the filter cap and wing nut

• Reinstall the filter cover.

Condensing Coil (Air Cooled Units)

The condensing coil should be cleaned weekly. Ensure that air pressure is removed from the system prior to cleaning

the condenser. The condenser can be cleaned by using a vacuum or compressed air. If the condenser is not clean

after it is blown out with compressed air or vacuumed contact the factory for assistance.

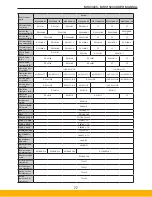

4.10 Remote PLC Operation

There are five inputs on the PLC dedicated to using external switches or relays to control the dryer operation.

These inputs require a 120VAC signal. Refer to the dryers wiring schematic for details.

Alarm Reset (PLC input 20)

• wired to a normally open SPST pushbutton switch or momentary PLC relay contact

• resets all alarms on the forward edge of the signal transition from off to on.

Run/Stop (PLC input-21)

• wired to a SPST toggle switch or latched plc relay contact

• starts the dryer on the forward edge of the signal transition from off to on.

• stops the dryer on the trailing edge of the signal transition from on to off.

Load/Unload Mode Select (PLC input 22)

• wired to a normally open SPST pushbutton switch or momentary PLC relay contact

• switches to load/unload mode on the forward edge of the signal transition from off to on.

Cycling Mode Select (PLC input 23)

• wired to a normally open SPST pushbutton switch or momentary PLC relay contact

• switches to cycling mode on the forward edge of the signal transition from off to on.

Auto Mode Select (PLC input 24)

• wired to a SPST toggle switch or latched plc relay contact

• Auto-Mode is enabled on the forward edge of the signal transition from off to on.

• Auto-Mode is disabled on the trailing edge of the signal transition from on to off.

NOTE: Proper noise consideration must be taken to avoid introducing noise into the control system. All switches

should have RC noise suppressors across the contacts. Wiring should be routed through metal conduits or shielded

cables grounded at the PLC chassis ground.

Summary of Contents for -W4P

Page 1: ...Magnum Refrigerated Air Dryers Models MSC4000 MSC15000...

Page 9: ...9 MSC4000 MSC15000 USER MANUAL Start Up Checklist...

Page 11: ...11 MSC4000 MSC15000 USER MANUAL...

Page 28: ...28 MSC4000 MSC15000 USER MANUAL 4 4 I O Screens...

Page 35: ...35 MSC4000 MSC15000 USER MANUAL Reference Guide...

Page 36: ...36 MSC4000 MSC15000 USER MANUAL...

Page 37: ...37 MSC4000 MSC15000 USER MANUAL...

Page 38: ...38 MSC4000 MSC15000 USER MANUAL...

Page 44: ...44 MSC4000 MSC15000 USER MANUAL...

Page 45: ...45 MSC4000 MSC15000 USER MANUAL...

Page 46: ...46 MSC4000 MSC15000 USER MANUAL...

Page 47: ...47 MSC4000 MSC15000 USER MANUAL...

Page 48: ...48 MSC4000 MSC15000 USER MANUAL...

Page 49: ...49 MSC4000 MSC15000 USER MANUAL...

Page 50: ...50 MSC4000 MSC15000 USER MANUAL...

Page 51: ...51 MSC4000 MSC15000 USER MANUAL...

Page 82: ...82 MSC4000 MSC15000 USER MANUAL 10 Associated Drawings...

Page 83: ...83 MSC4000 MSC15000 USER MANUAL...

Page 84: ...84 MSC4000 MSC15000 USER MANUAL...

Page 85: ...85 MSC4000 MSC15000 USER MANUAL...

Page 86: ...86 MSC4000 MSC15000 USER MANUAL...

Page 87: ...87 MSC4000 MSC15000 USER MANUAL...

Page 88: ...88 MSC4000 MSC15000 USER MANUAL...

Page 89: ...89 MSC4000 MSC15000 USER MANUAL...

Page 90: ...90 MSC4000 MSC15000 USER MANUAL...

Page 91: ...91 MSC4000 MSC15000 USER MANUAL...

Page 92: ...92 MSC4000 MSC15000 USER MANUAL...

Page 93: ...93 MSC4000 MSC15000 USER MANUAL...

Page 94: ...94 MSC4000 MSC15000 USER MANUAL...

Page 95: ...95 MSC4000 MSC15000 USER MANUAL...

Page 96: ...96 MSC4000 MSC15000 USER MANUAL...

Page 97: ...97 MSC4000 MSC15000 USER MANUAL...

Page 108: ...108 MSC4000 MSC15000 USER MANUAL...

Page 109: ...109 MSC4000 MSC15000 USER MANUAL...