B75 Series 1/4", 3/8", & 1/2" Filter / Regulators

IS-B75

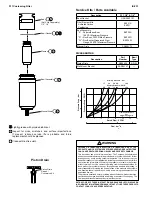

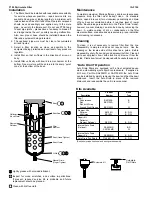

Adjusting Knob

Adjusting Screw Assembly

Bowl Assembly

(Hand Tight)

Inner Valve Assembly

(Disc Assembly) (Poppet)

Adjusting Spring

Bottom Spring

Filter Element

Filter Retainer

Bowl Gasket

Deflector

Diaphragm Assembly

Slip Ring

Regulator Body

(Not Sold Separately)

1/4", 3/8", 1/2"

Spring Cage (Bonnet) Assembly -

Torque: 11.3 to 13.6 Nm

(100 to 120 in. lb.)

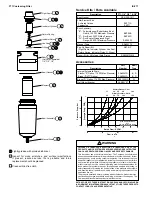

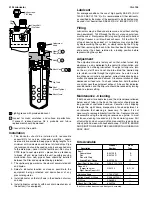

Service Kits / Parts Available

Description

R75, 1/4", 3/8", & 1/2"

Adjusting Knob (In Kit CKR75)

R35-0545P

Spring Cage (In Kit CKR75)

R75-0151P

Adjusting Screw Assembly (In Kit CKR75)

SAR55-0532

Adjusting Spring

“A” Range (0 – 25 PSI)

SPR-53

“B” Range (0 – 60 PSI)

SPR-54

“C” Range (0 – 125 PSI)

SPR-55

Slip Ring (In Repair Kit)

R55-0081

Diaphragm Assembly

Relieving (In Kit RKR75)

SAR75-0201

Non-Relieving (In Kit RKR75K)

SAR75-0202

Bowl Gasket (In Bowl Assembly Kit)

GSK-F55-1011

Deflector, Filter Retainer

RKF55

Inner Valve Assembly (In Kit RKR75)

SAR75-0371

Bottom Spring

SPR 391-1

Filter Element

“G” - 5 µ

EK55G

“J” - 40 µ

EK55J

Bowl Assembly

“B” - Polyurethane w Polyethylene Bowl

Guard, 150 PSI Maximum Pressure

BKF55B

“D” - Zinc Bowl, 300 PSI Max. Pressure

BKF55D

“W” - Zinc Bowl w/Wraparound Sight Glass,

250 PSI Maximum Pressure

BKF55W

Repair Kit

Relieving

RKR75

Non-Relieving

RKR75K

Spring Cage Kit

CKR75

Tamperproof (Not Shown)

CKR75T

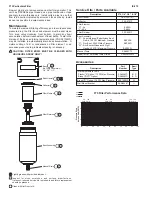

Accessories

Gauge

0 to 60 PSI (0 to 4 bar)

K4515N18060

0 to 160 PSI (0 to 11 bar)

K4515N18160

Panel Mount Nut *

Acetal Plastic

R05X51

Aluminum

R05X51-A

Wall Mount Bracket

SAR55Y57

Internal Automatic Drain

Plastic (“R” Option, 175 PSI Max. Pressure)

SA602MD

Brass

SA605MD

Brass (W Bowl Only)

SAF105MD

* Requires 1-1/4" hole (1-3/16-18 UNEF-2B)

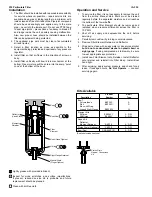

Installation

All QUBE components are individually tapped (NPT or BSPP) to allow

direct mounting to piping. Also, each FRL component comes equipped

with the necessary screws and O-rings to enable connection to other

QUBE components of the same series without the need for pipe nipples

or special adaptors. Before installing, blow out pipe line to remove scale

and other foreign matter. This unit has DRYSEAL pipe threads; use pipe

compound or tape sparingly to male threads only. Install units in pipeline

so that flow is with the arrows as indicated on the top of the body. Install

as near as possible to equipment serviced.

Reduced Pressure Adjustment

To adjust reduced pressure settings, pull knob out and turn knob

clockwise to increase pressure setting and counter-clockwise to lower

setting. Push knob in to lock adjustment. With relieving-type regulators,

the reduced pressure follows adjustment of the screw. With non-relieving

regulators, adjustment for lower reduced pressure will not be obtained

until the reduced pressure system is “bled-off” or until air flow starts.

Maintenance – Cleaning

Note: To clean, it is not necessary to remove regulator from line. Refer

to drawing as guide in reassembly. If the air supply is kept clean, the

regulator should provide long periods of uninterrupted service. Erratic

regulator operation or loss of regulation is most always due to dirt in

the disc area. To clean, shut off air line pressure and disassemble the

regulator. Refer to drawing as a guide to disassembly and subsequent

reassembly. Clean parts with household soap and blow out body with

compressed air. When reassembling make sure the disc is firmly in place

and that the disc stem fits into the center hole of the diaphragm assembly.

Tighten bowl assembly hand tight.