34

6K Hardware Installation Guide

Testing the Installation

Warning

— This test procedure allows you to control your system I/O and produce motion. Therefore, you

should make sure that exercising the I/O will not damage equipment or injure personnel.

Test Setup

1.

If you haven’t already done so, made the necessary communication connections (see page 28).

2.

Install Motion Planner (CD is provided in your ship).

3.

Launch Motion Planner and click on the “Terminal” window tab to view the terminal emulator. You now have live communication with

the 6K product.

Connections Test

Procedure

Response Format

(left to right)

End-of-travel

and

Home Limits

NOTE

:

If you are not using end-of-travel limits, issue the Disable Limits (

@LHØ

)

command and ignore the first two bits in each response field.

1.

Enable the hardware end-of-travel limits with the

@LH3

command.

2.

Close the end-of-travel switches and open the home switches.

3. Enter

the

TLIM

command. The response should be

*TLIM11Ø_11Ø_11Ø

…

4.

Open the end-of-travel switches and close the home switches.

5. Enter

the

TLIM

command. The response should be

*TLIMØØ1_ØØ1_ØØ1

…

6.

Close the end-of-travel switches and open the home.

7. Enter

the

TLIM

command. The response should be

*TLIM11Ø_11Ø_11Ø

…

TLIM

response:

bit 1 = Axis 1 POS limit

bit 2 = Axis 1 NEG limit

bit 3 = Axis 1 HOM limit

bit 4 = Axis 2 POS limit

bit 5 = Axis 2 NEG limit

bit 6 = Axis 2 HOM limit

and so on (3 inputs/axis)

“POS” means positive travel.

“NEG” means negative travel.

“HOM” means home.

Encoder

(not coupled to

the load or

motor)

1.

Enter these commands, (preset the RETURN key after each command):

ENCCNT1

,

L

,

TPE

,

T.3

, and then

LN

. This will begin a continuous display of all encoder

positions. Press the RETURN key to move the display to the next line and save the

current value.

2.

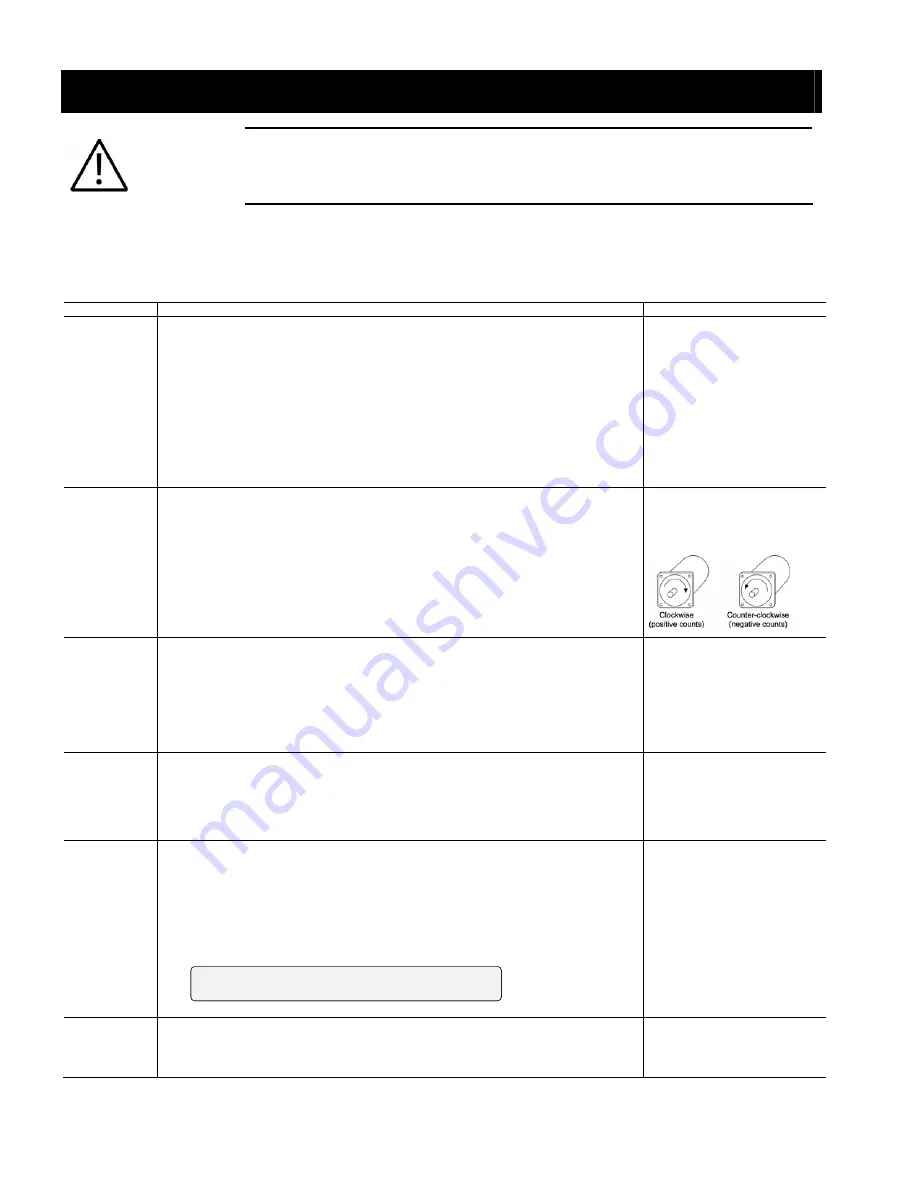

Manually rotate the encoder shaft and verify that the position changes as you rotate

the encoder shaft. If you connected the encoder as instructed earlier in this chapter,

moving the shaft clockwise should increase the position reading. If the reading does

not change, or if the direction is reversed, check the connections. If the direction is

reversed, swap the A+ and A- connections.

3.

When finished, enter the

^K

(ctrl-K) command to stop the continuous report-back.

TPE

response

(encoder counts)

:

±encoder1, ±encoder1, …

Direction of rotation:

Trigger Inputs

1.

Open the trigger input switches or turn off the device driving the inputs.

2. Enter

the

TIN

command.

Response should be

*TINØØØØ_ØØØØ_Ø

or

*TINØØØØ_ØØØØ_ØØØØ_ØØØØ_Ø

.

3.

Close the trigger input switches or turn on the device driving the inputs.

4. Enter

the

TIN

command.

Response should be

*TIN1111_1111_1

or

*TIN1111_1111_1111_1111_1

.

TIN

response:

Bits 1-n, from left to right,

represent trigger inputs 1-n.

Bit #17 represents the Master

Trigger (“MASTER TRG”).

The 6K2 & 6K4 have 9 inputs,

the 6K6 & 6K8 have 17 inputs.

Onboard

Outputs

1. Enter

the

@OUT1

command to turn on (sink current on) all programmable outputs.

Verify that the device(s) connected to the outputs activated properly.

2. Enter

the

TOUT

command. Response should be

*TOUT1111

or

*TOUT1111_1111

.

3. Enter

the

@OUTØ

command to turn off all programmable outputs. Verify that the

device(s) connected to the outputs de-activated properly.

4. Enter

the

TOUT

command. Response should be

*TOUTØØØØ

or

*TOUTØØØØ_ØØØØ

.

TOUT

response:

Bits 1-n, from left to right,

represent outputs 1-n.

The 6K2 & 6K4 have 4 outputs,

the 6K6 & 6K8 have 8 outputs.

RP240

1.

Cycle power to the 6K.

2.

If the RP240 is connected properly, the RP240’s status LED should be green and

one of the lines on the computer or terminal display should read

*RP24Ø

CONNECTED

. If the RP240’s status LED is off, check to make sure the +5V

connection is secure. If the RP240’s status LED is green, but the message on the

terminal reads

*NO REMOTE PANEL

, the RP240 Rx and Tx lines are probably

switched. Remove power and correct.

3.

Assuming you have not written a program to manipulate the RP240 display, the

RP240 screen should display the following:

COMPUMOTOR 6Kn CONTROLLER

RUN JOG STATUS DRIVE DISPLAY ETC

ASSUMPTIONS

RP240 connected to the COM

2 (“RS-232/485”).

COM 2

configured for RP240. To

verify, type these commands:

PORT2

<cr>

DRPCHK

<cr>

The system response should

report “

*DRPCHK3

”.

Enable Input

1.

Open the enable input (ENABLE) switch.

2. Enter

the

TINO

command. Response should be

*TINOØØØØ_ØØØØ

.

3.

Close the ENABLE switch.

4. Enter

the

TINO

command. Response should be

*TINOØØØØ_Ø1ØØ

.

TINO

response:

bit 6 = Enable (ENABLE) input,

all other bits are not used.

www.comoso.com