Axial Piston Pump

Series PV, series 47 and higher

Bulletin MSG30-3245-INST/UK

Installation manual

3

Parker Hannifin Manufacturing Germany GmbH & Co. KG

Pump & Motor Division Europe

Chemnitz, Germany

1. Installation and start-up

For a safe and disruption free operation of any

machine or system a careful installation and start

up according to the manufacturers instructions

is mandatory.

Hydraulic systems can be designed for many

totally different functions and they require con-

sequently different start up procedures. The

hydraulic pump is in this respect only one, but

nevertheless a very important component of the

whole system.

A general start up instruction therefore can give

many helpful hints but it needs to be completed

by specific additions depending of the individual

nature of the system or power unit.

During installation and start up the following steps

need to be carried out carefully:

Visual inspection

Make sure that all components of the shipment

are complete, free of any damage, free of outside

contamination and properly protected against

ingression of contamination.

Cleanliness

Contamination of any kind is the enemy of any

hydraulic component. It is still the number one

cause for component failure. Therefore

maxi-

mum care

and

cleanliness

are required during

all handling and managing of parts that come in

contact with the hydraulic fluid. All ports of the

pumps and other components must be covered

until pipes or hoses are mounted to them. Per-

form assembly preferrably in a dry and dust free

room. Use only suitable tools.

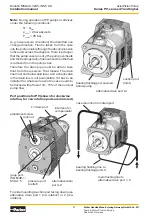

Installation

Installation horizontal or vertical, avoid rigid con-

nection from pump to reservoir cover or frame

and to inlet and outlet piping to prevent excitation

of the whole system due to pump vibrations.

Suction port

Position to the side or to the bottom, max. fluid

velocity approx. v = 1.0 m/sec, cut suction pipe

inlet under 45°. Minimum distance from bottom

2 – 3 times diameter and, even at lowest fluid

level, approx. 200 mm below fluid level. Inlet pres-

sure, even during compensation, never should

drop below 0.8 bar (absolute).

Absolute gas tight connection (risk of cavitation,

noise). Air bubbles due to vacuum in the inlet

can destroy pumps within a short time due to

cavitation erosion. Suction pipe should be as

short as possible. Use only clean, low pressure

pipe, avoid sharp elbows and any restriction of

cross section.

The suction pipe must have access to clean,

cooled and filtered fluid, free of air bubbles. No

turbulences or high flow velocities should occur

at the tube inlet. Therefore position inlet as far

as possible away from return line and drain line.

Make sure that the fluid circulation in the reservoir

does keep return flow from suction pipe inlet. In

case of positive head use shut off valve in the inlet,

monitored with proximity switch or equivalent to

avoid start up of motor when valve is closed. When

installed into the reservoir use short suction pipe

with pipe end cut under 45°.

Pressure port

Select correct pressure rating for pipe, hose and

connectors. Take pressure peaks into account.

Dimension the piping according to the port size.

Prevent excitation of the system by using flexible

port connections.

Drain port

Always use highest possible drain port of the

pump. Drain port must be higher than pump

centerline or install additional air bleed line. Never

combine pump drain line with other return lines

and/or drain lines. Pump shall not be able to run

empty. Max. allowable case pressure

≤

0.5 bar

(2 bar peak), also during compensation.

Use low pressure pipe/hose, as short as possible

and full cross section according to port dimen-

sion. Do not use elbows or sharp corners. When

drain port is on the side of the pump drain line

should have bridge higher than pump top (also

when installed in reservoir). Drain pipe must

end at least 200 mm below fluid level even at

lowest filling level. Never let drain flow go direct

into suction area of reservoir (temperature, air

bubbles). Max. length 2 m, otherwise use larger

pipe diameter than port size.