Bulletin MSG30-3245-INST/UK

Installation Manual

11

Parker Hannifin

Pump & Motor Division Europe

Chemnitz, Germany

Axial Piston Pump

Series PV, series 44 and higher

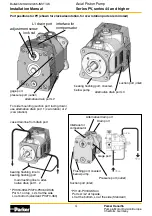

10. Compensator accessories

10.1 Pressure relief pilot valve, code

PVAC1P...

The pressure relief pilot valve code PVAC1P... is opti-

mally tuned for the requirements of the compensator

valves of the series PV. It has a mounting interface

NG6 according to DIN 24340 and can be mounted

directly on top of all compensator valves with the

topside mounting interface.

Such a valve is only necessary for the compensators

with elbow manifold (...MT1 and ...UPR) and for the

versions without integrated pressure pilot cartridge

(compensator code ends with..Z). Al other versions

include an integrated pilot valve.

lock nut

set screw

After loosening the lock nut SW13 an adjustment of

the compensating pressure for the pump is possible

in a range of approx. 20 bar up to 350 bar.

The pressure pilot valve is also available with a DIN

lock.

10.2 Multiple pressure pilots PVA-

C1E..., PVAC2P..., PVAC2E... und

PVAC2M...

For multiple pressure pilots, codes PVAC2P...,

PVAC2E... and PVAC2M... a sandwich valve with

two direct-action pressure cartridge valves is used

to pilot the pump.

For code

PVAC2P...

a single solenoid directional

control valve is included for pressure selection. The

valve switches between low pressure setting and

high pressure setting. During low pressure both pilot

cartridges are connected to the compensator, in the

high pressure setting (solenoid energized) only the

A-side cartridge is connected. Therefore the B-side

pilot needs to be set for lower pressure. The direc-

tional control valve series D1VW has spool code 6.

For code

PVAC2E...

for pressure selection a two-

solenoid DCV is included, which selects between low

pressure setting, high pressure setting and stand-by

pressure. In neutral position both cartridges are con

nected to the compensator valve. The lower pressure

defines the compensating pressure of the pump.

When the A solenoid (B-side) of the DCV is energized

only the A-side cartridge is connected; the (higher)

pressure adjusted there defines the compensating

pressure.

When solenoid B is energized the valve spool con-

nects all four ports. Then the spring chamber of the

compensator valve is directly relieved to the case

drain of the pump, the pump compensates at mini-

mum compensating pressure (stand-by).

The directional control valve series D1VW has spool

code 55. This spool code is used to avoid a blocked

spool position during transient.

This version is recommended, when during a ma-

chine cycle the pressure is to be switched between

high and low.

For code

PVAC2M...

also a dual solenoid valve is

used. In neutral position all four ports are connected.

The compensator spring chamber is releived to case

drain, the pump is compensating at min. compensat-

ing pressure (stand-by).

When energizing solenoid A (B-side) the spring

chamber is connected to the A-side pilot cartridge;

the pressure adjusted here controls the pump.

When solenoid B is energized the spring chamber

of the compensator is connected to pilot cartridge B;

then the pressure adjusted on this cartridge defines

the pump compensating pressure. The DCV of series

D1VW has spool code 2.

This version should be used, when stand-by operation

should be the default situation.

Code

PVAC1E...

is similar to code PVAC2P..., with the

exception, that only one pilot cartridge is installed. In

neutral position of the D1VW the stand-by pressure

is selected.

Additional information can be found in:

compensator spare parts manual PVI-PVC-UK-45

compensator accessories spare parts manual

PVI-PVAC-UK

pumps spare parts manuals PVI-***-UK-45 with *** =

BG1 to BG5 according to pump frame size.

P

T

P

T

P

T

P

T

P

T

p

1

p

1

p

1

p

2

p

2

(>p

2

)

A

B

P

T

A

B

P

T

A

B

P

T

PVACPP

PVAC1P...

PVAC2P...

(PVAC2E...)

PVAC1E...

PVAC2M...