Bulletin MSG30-3245-INST/UK

Installation Manual

10

Parker Hannifin

Pump & Motor Division Europe

Chemnitz, Germany

Axial Piston Pump

Series PV, series 44 and higher

Depending on its type, the horse power compensator

consists of a remote pressure com pen sator or a load

sensing compensator in combination with the horse

power pilot cartridge. The opening pressure of this

pilot cartridge depends on the actual displacement

of the pump. At large displacements the opening

pressure is low. As the displacement is reduced

the opening pressure is increased according to the

form of the contour sleeve in the pump. That leads

to the desired control characteristic (constant input

horse power).

That is achieved by having the pilot cartridge seat

being guided by the contour sleeve. This contour

sleeve is firmly connected to the servo piston. The

contour represents the desired input horse power.

The horse power pilot cartridge is internally con-

nected to the compensator valve. Compensator

valves for horse power compensated pumps differ

from standard compensator valves only in the fact,

that a plug in a connecting hole is removed.

For a standard horse power compensator with order-

ing code ...*L* a modified remote pressure compen-

sator is used. For a horse power compensator with

load sensing, code ...*C* a modified load sensing

compensator is used.

Constant horse power curve with adjustment

9. Horse power compensator, codes

...*L*, ...*C*

Adjustment A: tolerance compensation for optimized

performance; done at pilot cartridge.

Adjustment B: maximum pressure setting; done at

integrated pressure pilot valve.

At the adjustment screw of the horse power pilot valve

a basic adjustment of the horse power compensator

can be made. After loosening the lock nut (self sealing

nut) the compensator control curve can be moved

by turning the adjustment screw (adjustment A in

the diagram left). This adjustment, done to meet the

required constant input horse power curve, is already

made during the factory test and should be modified

only in exceptional cases.

To adjust the correct constant horse power curve

a measuring device is required. An output power

measurement requires pressure and flow metering.

An input power measurement requires torque and

speed measurement or a measurement of the electric

motor current.

Note: For horse power control the load sensing dif-

ferential is set to 15 ± 1 bar. Any change will result in

a deviation from the horse power setting.

Note

: The setting is very sensitive, 0,1 mm change

of the spindle changes the pressure approximately

20 bar.

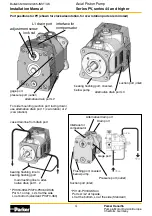

Partial section through a horse power controlled

pump

Horse power pilot cartridge

adjustment spindle

lock nut

pilot cartridge

compensator valve

contour sleeve