INSTRUCTIONS CM340B

For Instructions in Local Languages

and Technical Support:

www.panduit.com/resources/install_maintain.asp

E-mail:

Fax

:

(708)444-6448

www.panduit.com

Page 28 of 28

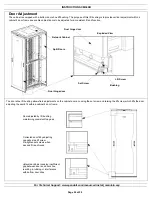

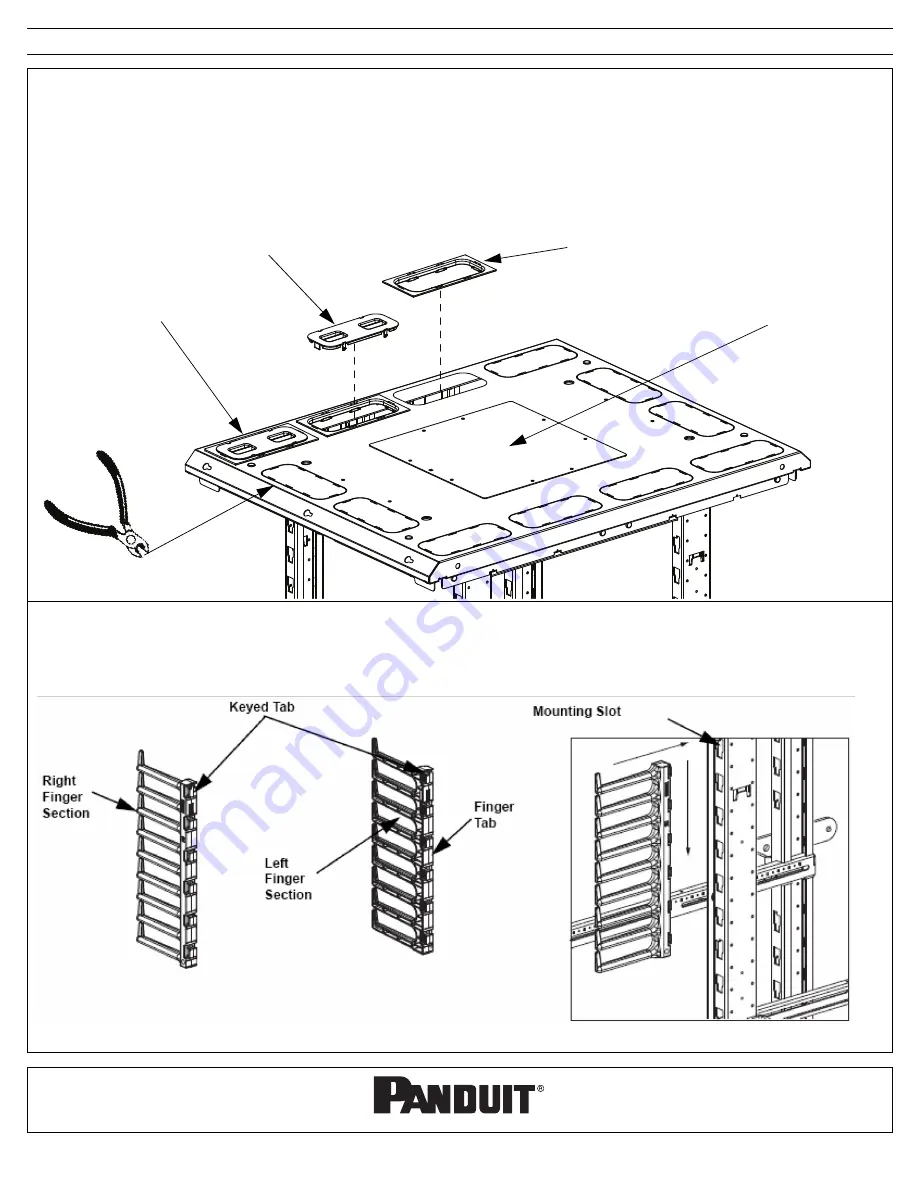

Cable Management Installation

Included in the cabinet are cable management fingers sections (5 Right 5 Left). Cable management can be installed where desired by inserting

the tabs on the rear of the finger sections in the mounting slots slot located on the four (4) cabinet posts and sliding downward. To remove

reverse the process.

Note:

The top mounting tab and mounting slot are keyed to allow proper alignment with rack units

Removable Cover

Overhead Cable

Opening Bezel

Overhead Cable

Opening Bezel

(INSTALLED)

Center Top

Plate

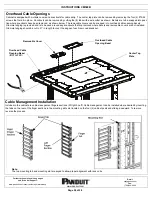

Overhead Cable Openings

Cabinet is equipped with multiple covers and knockouts for cable entry. The center top plate can be removed by removing the four (4) #12-24

screws that hold it in place. Knockouts can be removed by cutting the (8) tabs with a wire cutter as shown. Bezels are to be snapped into posi-

tion where knockouts have been removed, as shown below. The removable covers can be snapped into overhead cable opening bezels.

Grommet edging is provided and is to be used around any knockouts that are removed where bezels and removable covers are not installed.

Grommet edging should be cut to 21” in length to cover the edges of each removed knockout.