225

FEB 2008

Ver. 1.1

DP-C405/C305/C265

3.16. Adjusting Scanner Skew

Note:

Before adjusting Scanner, proceed the Printer Registration first. Refer to sect. 3.13.

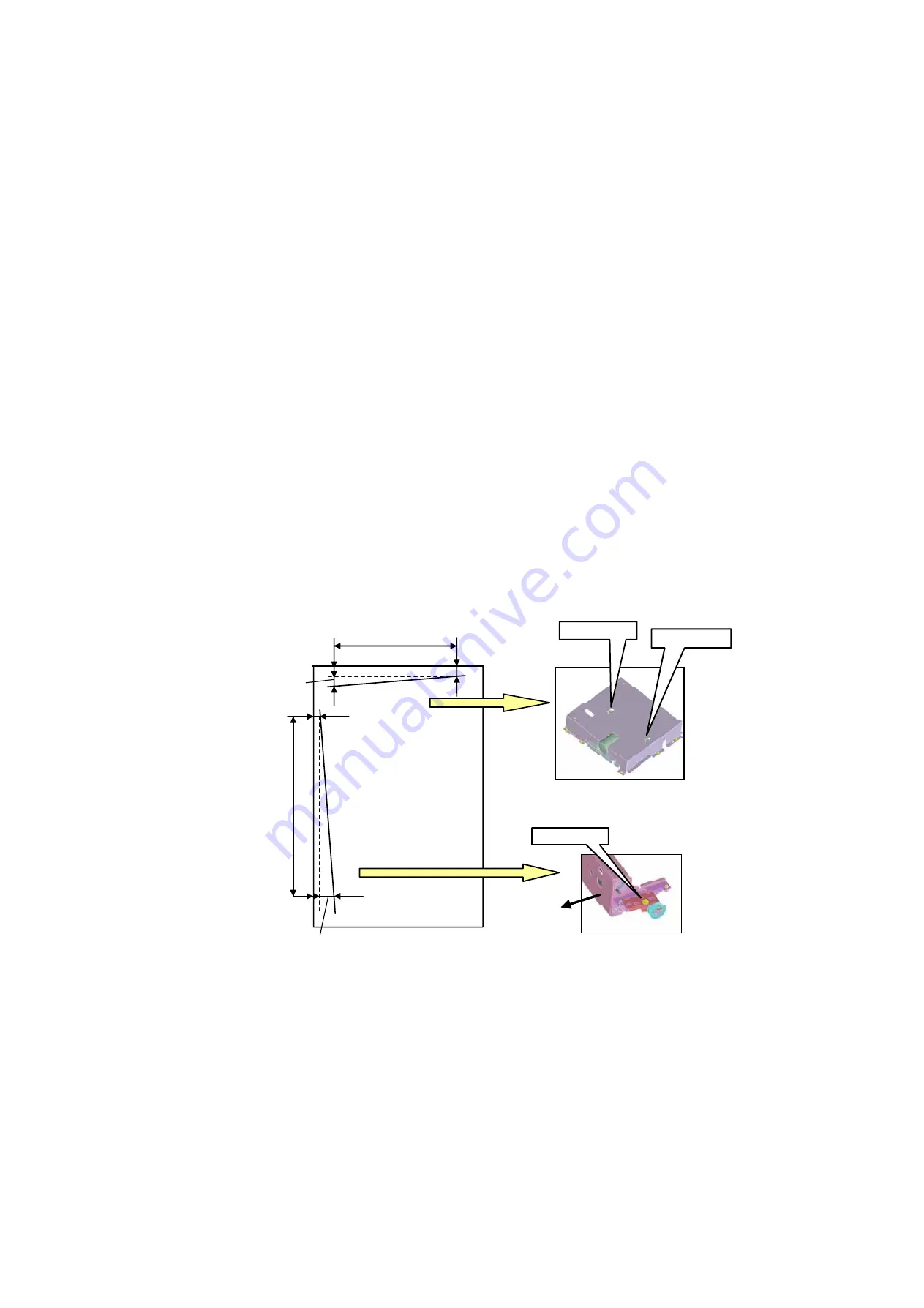

<Leading Edge>

1. Remove the

Glass Assembly

, refer to Section 2.2.2.

2. When the printed image is skewed to the left as illustrated.

a. Turn Screw (A) Clockwise.

b. Turn Screw (B) Counterclockwise.

Note:

(1) Turn both Screws (A), and (B) for each adjustment by the same amount.

(2) Amount of adjustment: Half a turn of both screws, adjusts the skewed image by approximately

0.0275 in (0.7 mm).

(3) Do not turn 2-3 turns at once.

<Side Edge>

1. Remove the

Glass Assembly

, and move the

Scanner Front Cover

, refer to Section 2.2.3.

2. When the printed image is skewed to the left as illustrated.

a. Loosen the Screw (C).

b. Slide the Mirror Frame 2 in the direction illustrated below.

Note:

(1) Amount of adjustment: Sliding the Mirror Frame 0.0394 in (1 mm) in the Direction (D), adjusts the

skewed image by approximately 0.0315 in (0.8 mm).

(2) Do not slide the Mirror Frame 2-3 mm at once.

Screw (A)

Screw (B)

7.87 in (200 mm)

11.81 in

(300 mm)

<Leading Edge>

<Side Edge>

Screw (C)

Sliding

Direction (D)

Amount of Adjustment:

Amount of

Adjustment:

0.0275 in (0.7 mm)

/ Half Turn

0.0315 in (0.8 mm) / 0.0394 in (1 mm) Slide

Summary of Contents for Workio DP-C305

Page 2: ...2...

Page 3: ...3...

Page 5: ...5...

Page 6: ...6 For PB and Other Destinations not for PU USA Canada...

Page 11: ...11...

Page 12: ...12...

Page 13: ...13...

Page 14: ...14 memo...

Page 220: ...220 FEB 2008 Ver 1 1 DP C405 C305 C265 Color Test Chart 101 P N PJQRC0119Z LDR PJQRC0120Z A3...

Page 232: ...232 FEB 2008 Ver 1 1 DP C405 C305 C265 3 20 720K PM Kit DQ M35S72 DQ M32N72...

Page 400: ...400 FEB 2008 Ver 1 1 DP C405 C305 C265 LVPS CN6 LVPS CN7 Refer to SCN PC Board...

Page 401: ...401 FEB 2008 Ver 1 1 DP C405 C305 C265 LVPS CN8 Europe Specification Only...

Page 404: ...404 FEB 2008 Ver 1 1 DP C405 C305 C265 CST PCB CN603 CST PCB CN604...

Page 405: ...405 FEB 2008 Ver 1 1 DP C405 C305 C265 CST PCB CN605...

Page 406: ...406 FEB 2008 Ver 1 1 DP C405 C305 C265...

Page 407: ...407 FEB 2008 Ver 1 1 DP C405 C305 C265 CST PCB CN606...

Page 408: ...408 FEB 2008 Ver 1 1 DP C405 C305 C265...

Page 409: ...409 FEB 2008 Ver 1 1 DP C405 C305 C265 CST PCB CN607...

Page 410: ...410 FEB 2008 Ver 1 1 DP C405 C305 C265 CST PCB CN608...

Page 412: ...412 FEB 2008 Ver 1 1 DP C405 C305 C265 TRU PCB CN613...

Page 414: ...414 FEB 2008 Ver 1 1 DP C405 C305 C265 RLB PCB CN176...

Page 615: ...615 DP C405 C305 C265 FEB 2008 Ver 1 1 1 2 3 4 5 6 7 8...

Page 752: ...752 FEB 2008 Ver 1 1 DP C405 C305 C265 memo...

Page 847: ...847 DP C405 C305 C265 FEB 2008 Ver 1 1 2 Motor PCBs Fig 5 009 M1 M2 M8 M5 M4 M3 M7 M6 1...

Page 919: ......

Page 920: ...Published in Japan...