18

N OT E

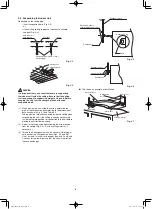

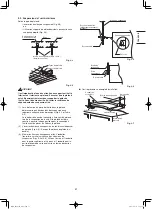

(1) Check the following items before performing the setting-check operations or auto airflow volume operations.

1) Check to make sure that the electrical wiring and ducting have been completed. Activate the stand-by mode. In particular, make

sure that the closed damper located in the middle of the duct is open, if installed. Also, make sure that air filters have been

installed inside the air inlet duct.

Check to make sure air is not leaking from the joints.

2) If multiple air outlets and air inlets are included, adjust the airflow volume ratio of all of them until they meet the design airflow ratio.

3) Make sure the address setting has been completed.

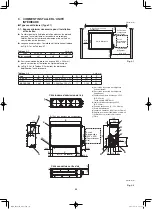

(2) The operation check will be completed in approximately three minutes if the settings have been made correctly. The settings will be

modified if they are out of the range of use (maximum 30 minutes.). If this is not completed within 31 minutes, check whether the air

speed is set to “H” or not.

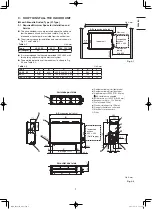

8. EXTERNAL STATIC PRESSURE SETTING

This section is described in the instruction manual supplied with the timer remote contoller (CZ-RTC2).

Regarding the High-spec Wired Remote Controller (CZ-RTC3), refer to the instruction manual supplied with the model CZ-RTC3.

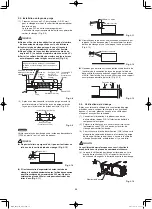

Choose one of the following methods from “a”, “b”, “c” or “d” as shown in the flow chart (within the dotted lines) and then make the

setting accordingly.

a. No setting modification............................................................ : Use-as-is at shipment (there are cases in which the setting may differ

from the shipment setting when reset after once setting the external

static pressure.)

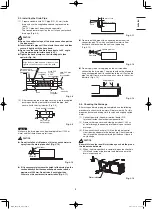

b. Manual setting (set with the PC board) ................................... : For high static pressure. Switching method with the short-circuit

connector.

c. Manual setting (set with the wired remote controller) ............. : Low static pressure ~ high static pressure

d. Auto airflow volume setting (set on the wired remote controller) .... : Air outlet volume is automatically adjusted to the rated airflow volume

with the auto airflow control drive.

Flow of External Static Pressure

Finish the ducting and electrical wiring and prepare it for use. (Note (1))

External static pressure should be set during initial operations after installation (before

the cooling and heating test run).

When operating with group control (connecting multiple indoor units with one wired

remote controller), make the low silhouette ducted type to the main unit.

Start external static pressure setting

a. No setting modification

b. Manual setting

(set with the PC board)

TP3 or TP1 short-circuit

Refer to section “8-1. How to

Set on PC Board”.

c. Manual setting

Item code “b0” : 0~15 setting

(*Note (3)) (* Note (4))

Refer to section “8-2. Operating

the Timer Remote Controller

(CZ-RTC2)”.

d. Auto airflow volume setting

(* Note (4)) Item code “b0” :

-2 setting

Refer to section “8-2. Operating

the Timer Remote Controller

(CZ-RTC2)”.

Operation checks for external static pressure settings (*Note (2))

Refer to section “8-2. Operating the Timer Remote Controller (CZ-RTC2)”.

Check if the setting is within the range of use on the PQ diagram.

If out of range, adjust until it becomes within the range of use.

This can be omitted if deemed unnecessary in the event of the same installation/set-up being available.

Auto airflow volume control

operations

(*Note (5))

Refer to section “8-2. Operating

the Timer Remote Controller

(CZ-RTC2)”.

Test operation display will disappear. (*Note (6))

External static pressure setting completed

Timer remote controller available

Lines

15

and

14

settings (high static pressure) on

the PQ diagram required

Set the rated airflow

volume with the exception of lines

15

,

14

and,

8

Line

8

(set at

shipment) on the PQ diagram

designed and installed

No

No

No

No

Yes

Yes

Yes

Yes

II̲09̲F616388̲EU̲L.indb 18

II̲09̲F616388̲EU̲L.indb 18

2013/12/11 15:12:26

2013/12/11 15:12:26