35

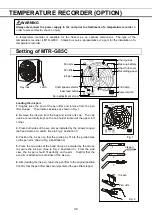

BACKUP COOLING KIT (OPTION)

WARNING

As with any equipment that uses CO

2

or N

2

, there is a likelihood of oxygen depletion in the vicinity

of the equipment. It is important that you assess the work site to endure there is suitable and

sufficient ventilation. If restricted ventilation is suspected, then other methods of ensuring a safe

environment must be considered. These may include atmosphere monitoring and warning

devices.

This freezer can be provided with a backup cooling kit (CVK-UB2 CVK-UB2I)/ CVK-UBN2) which is an

optional component. For the installation, refer to the instruction manual enclosed with the backup cooling

kit.

Contact our sales representative or agent for the installation of a temperature recorder.

1.

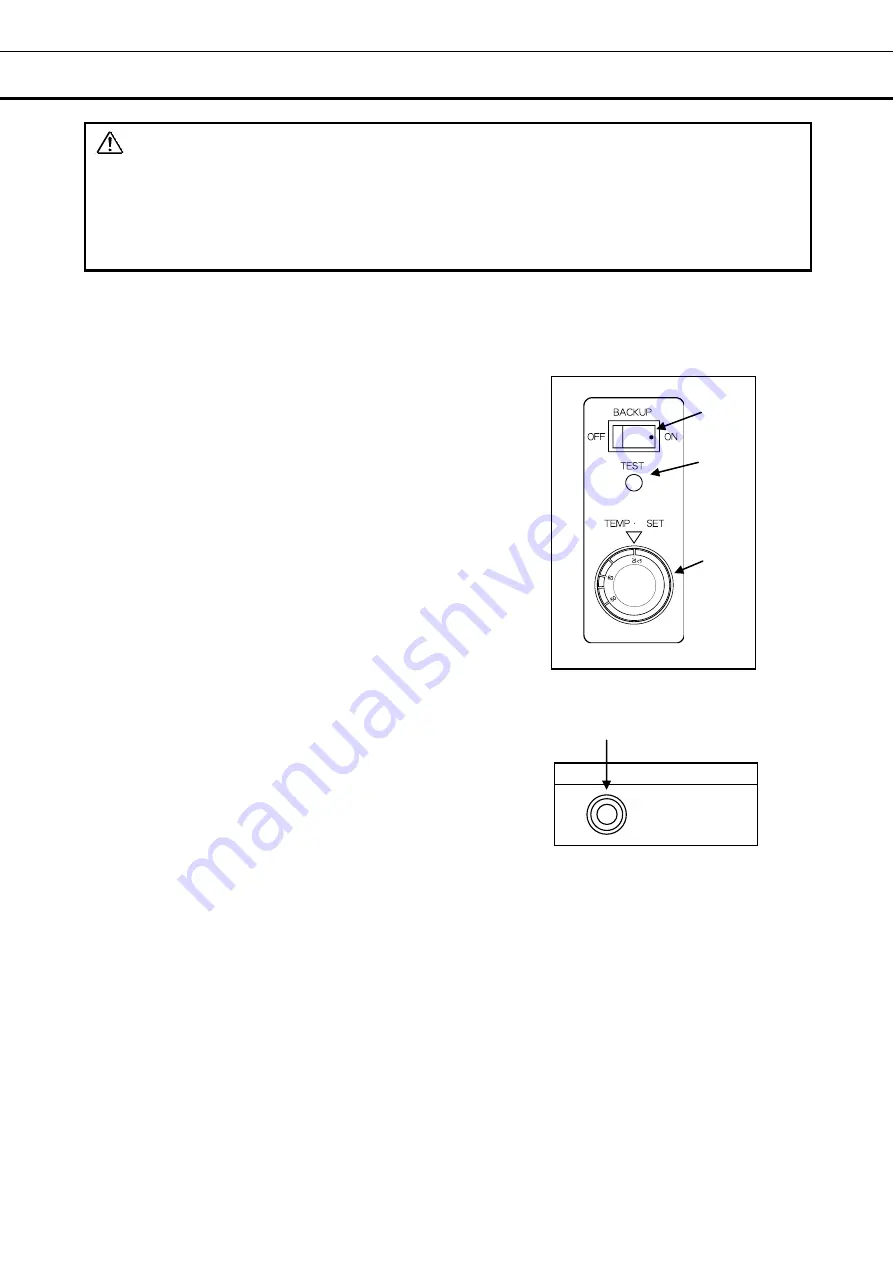

Switch of backup cooling kit (BACKUP)

When turning on the backup cooling kit, the backup

standby lamp is brightened. This means that the backup

cooling kit is ready. To stop the operation of the

backup cooling kit, turn off this switch.

2.

Test switch (TEST)

This switch is for checking the operation of backup

cooling kit. Pressing this switch is resulted in the

release of liquid carbon dioxide without backup cooling

kit operation.

3.

Temperature setting knob (TEMP. SET)

With this knob, set the temperature at which the backup

cooling kit is operated. The effective set temperature

range is between -50

o

C and -70

o

C.

Note:

Do not set the temperature setting knob to the

temperature lower than -70

o

C to avoid the early

consumption of CO

2

or N

2

gas resulting from continuous

injection.

Do not set it up in less than -70

o

C.

4.

Backup standby lamp (BACK UP STANDBY)

This lamp is on/off conjunction with the operation of

switch of backup cooling kit.

1

2

3

BACK UP

STANDBY

4

Door switch box