Loading Documents

15

4

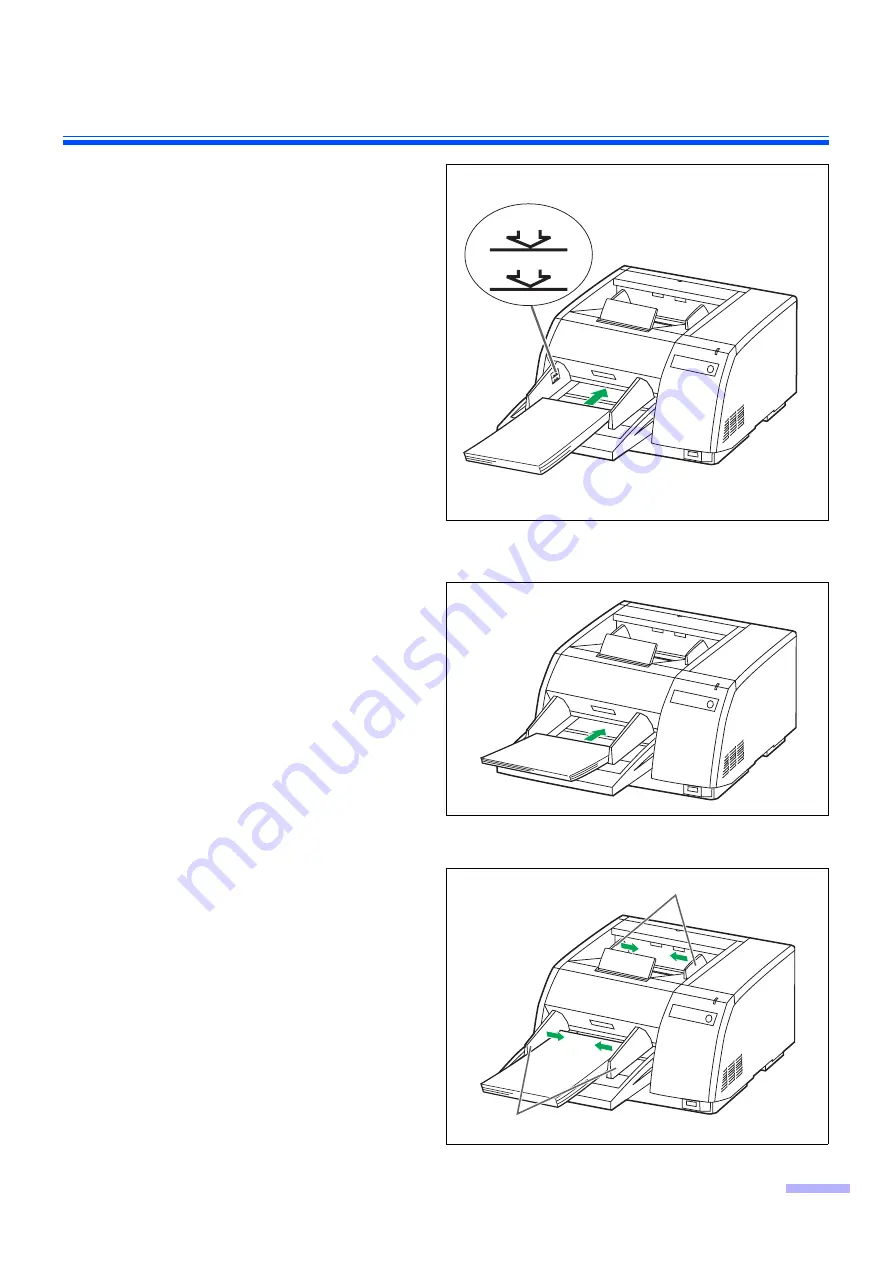

Place the documents on the hopper

with the side to be scanned facing up.

Then push them in the direction of the

arrow until they stop.

≥

Be sure to place the documents on the

hopper as shown in the diagram at the

right.

The amount of documents should not

exceed the limit mark on the document

guide. This may cause a paper jam or

skew.

≥

The scanning document size is different

for the KV-S3065CL and KV-S3065CW.

Please refer to

“Specifications”

for details.

≥

For documents up to A4, letter or legal

size, up to 300 sheets of 64

g

/m

2

(17 lbs.)

paper can be placed at one time on the

hopper. For documents up to B4, A3 or

ledger size, up to 200 sheets of 64

g

/m

2

(17 lbs.) paper can be placed.

≥

Even with A4, letter and legal size docu-

ments, the maximum number of sheets of

paper which can be inserted when the

documents are to be scanned in the land-

scape mode is 200 which is the same

number as for the B4, A3 and ledger size

documents. (This is the number of sheets

that comes up to the B4-A3 limit mark.)

≥

Depending on the types of paper, the doc-

ument may slip and not be fed smoothly.

In such case, reduce the number of

sheets of the document.

5

Adjust the document guides to the size

of the document to be scanned.

Adjust the exit document guides to the

size of the document to be output, if

required.

A4, LTR

B4

T

A3

A

A4

, L

TR

B4

T

A3

Portrait

Fill indicator

(Limit mark)

The fill indicator illustration is only for the KV-S3065CW.

A

Landscape

A

Exit document guides

Document guides

Summary of Contents for KV-S3065

Page 6: ...Notice 6 Caution Labels ...