Aurora H2O User’s Manual

13

Chapter 3. Operation and General Programming

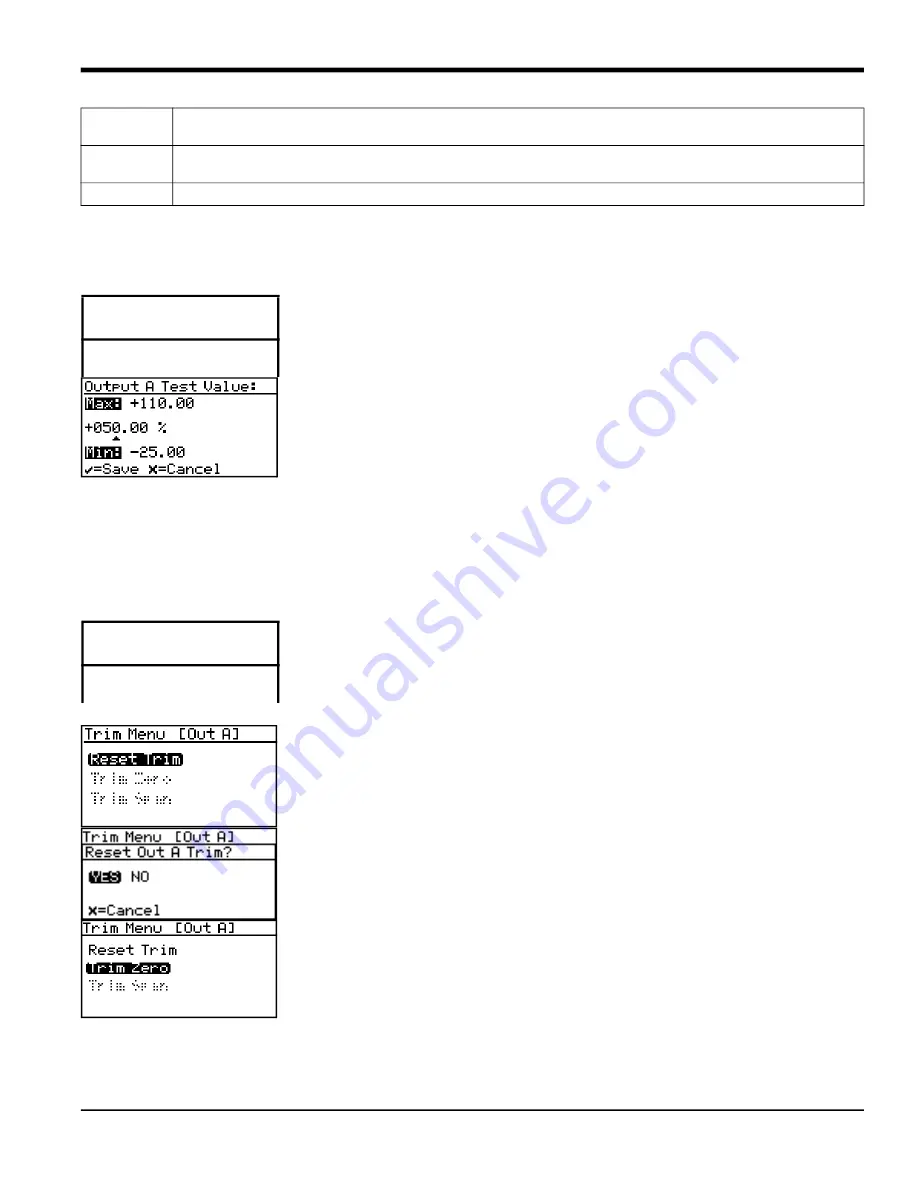

3.5.7 Testing the Output

The

Test Menu

causes the

Aurora H2O

to generate a 0- or 4-20mA output at the

percent of scale selected. For example, in 4-20 operation, 0% = 4mA, 50% = 12mA, 100%

= 20mA. This allows the proper function of recording or SCADA equipment to be

verified. In 0-20 operation, 0% = 0mA, 50% = 10mA, 100% = 20mA.

To test system output, from the

Output Menu

select

Test

and press

Enter

. The

Aurora H2O

will proceed to check the settings, and a screen similar to this display will appear.

Use the left and right arrow keys to select each digit to be changed, and the up and

down arrow keys to increase or decrease its value. Press

Enter

to save (or

Cancel

to

keep) the previous value, and return to the

Output Menu

.

Check your output wiring. If the reading on your SCADA or DCS is off slightly, then

you may use the

Trim

feature to trim the output zero or span.

3.5.8 Trimming the Outputs

The

Trim Menu

enables the operator to compensate for differences in measurement of the 0/4-20 mA outputs by

connected recorders or SCADA equipment. To trim the output:

Select

Trim

from the

Output Menu

and press

Enter

. The following screen appears.

Note:

The trim applies to whichever output is chosen with the Select menu item, and

displayed on the menu title bar.

When performing a

Trim

operation, the

Aurora H2O

unit requires you to first reset the

trim. To reset the trim output, highlight

Reset Trim

and press

Enter

. The following screen

appears.

Use the left or right arrow keys to highlight

YES

and press

Enter

. This cancels any

previous trim values, and returns the

Aurora H2O

to its factory adjustment. The display

returns to the previous screen with

Trim Zero

highlighted.

To trim the zero value, press

Enter

. A screen similar to the following appears.

This will cause the

Aurora H2O

to output 4.000 mA on the output being trimmed. The

output value should then be read using the connected recorder, SCADA equipment, or

DVM. Enter the value read from the connected equipment as the

Zero Trim

value, as

follows:

HiRng

Over Range errors are inhibited; NAMUR signaling will NOT occur for Over Range error conditions.

NAMUR signaling will occur for all other errors in the table above.

Lo+Hi

Under Range AND Over Range errors are inhibited; NAMUR signaling will NOT occur for these error

conditions. NAMUR signaling will occur for all other errors in the table above.

ALL

ALL errors are inhibited; NAMUR signaling will NOT occur for any error in the table above.

Output Menu [Out

A]

Select

Lower

Units

NAMUR

Output Menu [Out

A]

Select

Lower

Units

NAMUR

Summary of Contents for Aurora H2O

Page 1: ...panametrics com 910 317 B August 2022 Aurora H2O User s Manual...

Page 2: ......

Page 4: ...ii no content intended for this page...

Page 12: ...Chapter x Aurora H2O User s Manual no content intended for this page...

Page 24: ...Chapter 1 Features and Capabilities 12 Aurora H2O User s Manual...

Page 44: ...Chapter 2 Installation 20 Aurora H2O User s Manual...

Page 47: ...Aurora H2O User s Manual 28...

Page 65: ...Chapter 3 Operation and General Programming 18 Aurora H2O User s Manual...

Page 96: ...Aurora H2O User s Manual 36...

Page 120: ...Chapter 5 AuroraView Interface Software 24 Aurora H2O User s Manual...

Page 140: ...Chapter 7 Troubleshooting 6 Aurora H2O User s Manual...

Page 148: ...Appendix A MODBUS RTU TCP Communications 14 Aurora H2O User s Manual...

Page 166: ...4 Aurora H2O User s Manual...

Page 168: ...Warranty 6 Aurora H2O User s Manual no content intended for this page...

Page 169: ......