ILK

22/33/44/55/66

I

NSTALLATION

M

ANUAL

Revision 1.6

- 29 -

5.9

Fork lift locks installation for re-enforced platforms

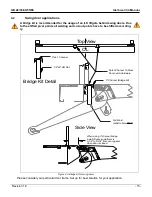

1. Install optional forklift locks to the outside of chassis frame. Angle slightly as shown to prevent

extension due to vibration while driving.

2. Set Fork Lock Assembly so the Slide Tube completely supports the Lift Arm Torsion Tube.

3.

Apply full length ¼” Min. fillet welds on Receiver Tube.

Forl Lift Lock Assy

Lubricate with Silicon based spray at every service to prevent rusting

5.10

Final Welding

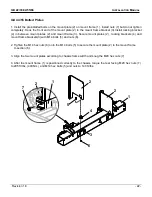

Make sure to have power pack pulled out and hoses and cables are away from walls

when welding the tube

Protect all wires from dropping slag or splatter when welding mount plates.

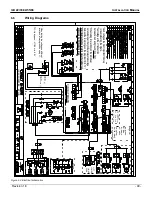

1. Verify the platform is in the correct position in relation to truck sill.

2. Weld tube and mount plates (and lower gusset on 5500 and 6600

lb models) with a 1/4” fillet weld

100% of the area around mount tube and around frame on both sides of plates. The plates must

have a minimum of 8” of overlap on the frame. PALFINGER Liftgates

recommends adding ¼” flat

bar or plate to the top of mount plates if needed to tie Liftgate mount plates to body stringer.

Chassis/Trailer Frame

Mount Plate

Mount

Tube

8" Min

100% 1/4" Fillet Weld on

both sides of Mount Plate

100% 1/4" Fillet Weld