ILK

22/33/44/55/66

I

NSTALLATION

M

ANUAL

Revision 1.6

- 16 -

Gate and Platform Installation

Refer to 4.1 for flip-up door/full seal kit and swing door applications BEFORE INSTALLATION

Refer to 5.2 for installs with Mounting Fixture BEFORE INSTALLATION

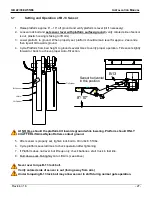

5.1

Sill Preparation

1. Reinforce back sill by welding a ½

” flat bar to the rear, 8 welds each on top and bottom.

2. Notch rear sill, if necessary, per installation table (Section 3.1) for your particular model.

3. Box in notch with flat bar to maintain sill strength.

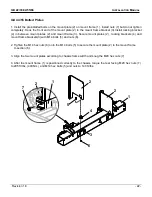

5.2

Installation with mounting fixture

1. Locate and mark out the center of the rear body or bed sill.

2. Attach the PALFINGER Liftgates

mounting fixture centered to the sill by tack welding it in place.

(The mounting fixture must be ordered separately from PALFINGER Liftgates. Once purchased it

can be used over and over)

3. Tie tilt cylinders with rope or wire to lift arm to avoid dragging on the ground

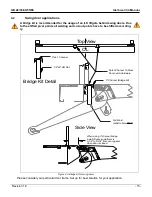

Figure 5.1: Mount fixture welded to rear sill

4. Prepare the body for the mount plates. The mount plates lie flat against body rail/ truck frame/ sub

frame.

5. Slide mount tube under the truck frame/ sub frame and attach the lift arm to the mounting fixture. At

this point you should place the mount tube in the pre-determined position, keeping the given

maxi-

mums and minimums in mind

(K- and F- dimensions). Use a forklift, a floor jack or a similar device

to position the mount tube. Make sure

the mount tube is placed at a 90-degree angle to the

truck bed

.

Attach lift arm here

Always make sure to

pursuit the policy of

MAXIMUM GROUND

CLEARANCE

BACKVIEW

Mounting

Fixture

SIDEVIEW