©2016 PACE Inc., Vass, North Carolina,

All Rights Reserved

Page

12

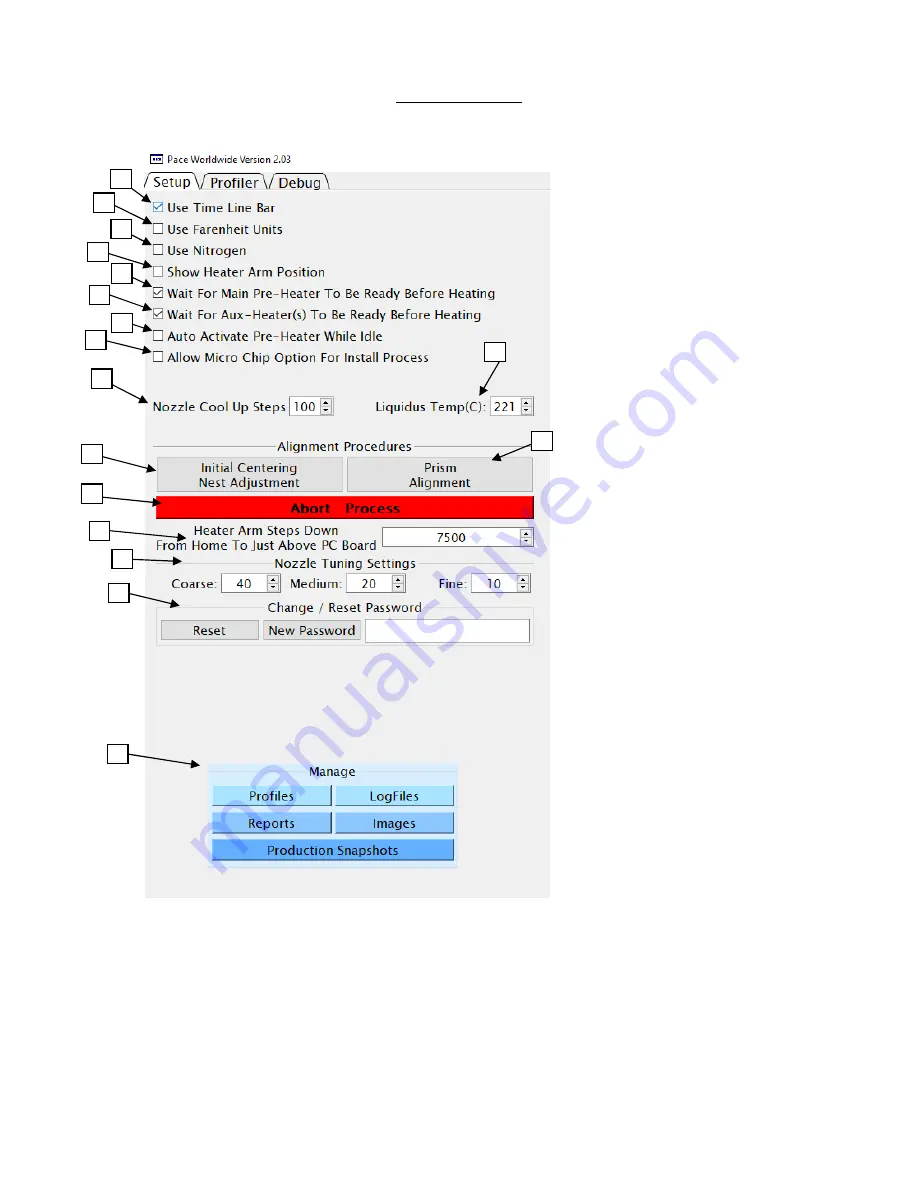

The Setup Screen

A) Use Timeline Bar – Turns on/off

the progress meter at the top of

the Profiler screen.

B) Use Fahrenheit Units –

Switches the default

temperature units to Fahrenheit

from Celsius.

C) Use Nitrogen – Check this when

using a pressurized nitrogen

supply instead of the ambient

air from the internal pump.

D) Show Heater Arm Position –

This checkbox will add an entry

to the Profiler screen called

“Arm Pos” which displays a

numerical value corresponding

to the heater head position.

E) Wait for Main Preheater Ready

– Checking this box will prevent

starting a profile until the

preheater has reached the

temperature setting for the

Preheat Zone.

F) Wait for Aux Preheater Ready –

Checking this box will prevent

anyone from beginning a profile

until the auxiliary preheaters

have reached the temperature

setting for the Preheat Zone.

G) Auto Activate Preheater while

idle – Checking this box will

allow the preheater to begin

heating as soon as the machine

is turned on, before a profile is

loaded.

H) Allow Micro Chip Option – This

controls whether or not the

Micro Chip automation process

will be available for selection on

the Profiler screen.

I) Nozzle Cool Up Steps – This sets the distance between the PCB and nozzle during Active Cooling.

Lifting the nozzle will allow increased airflow and faster cooling.

J) Liquidus Temp (C) – This is where to input the temperature used for calculating the “Time above

liquidus” shown on the Profiler screen. The liquidus temperature will vary depending on your specific

solder.

K) Prism Alignment – This function is used to calibrate/verify the camera prism is properly aligned.

A

B

C

I

F

G

H

J

D

L

K

M

N

O

P

E

Q