Service work

490E75=0_C

Ottobock | 15

4.5.2 Operating the seat height and seat tilt

All instructions for power operation of the seat height (optional) and seat tilt (optional) are included in the instructions

for use (user).

INFORMATION

If there is a defect in the seat height adjustment actuator, the seat height cannot be power operated. In this case,

please observe the following instructions:

f

If the seat is fixed in an upper position:

Actively secure the seat and the wheelchair against falling and tipping during all work. Perform the work only

with the active support and assistance of a helper, especially when the seat is folded up.

f

If the seat is fixed in the lowered position:

Check whether the seat can be pulled up manually for work on the seat height adjustment actuator. Actively

secure the manually raised seat and the wheelchair against falling and tipping. Perform the work only with the

active support and assistance of a helper, especially when the seat is folded up.

f

If the seat cannot be pulled up manually:

Carefully fold up the seat for the required work. Actively secure the seat and the wheelchair against falling and

tipping during all work. Perform all work only with the active support and assistance of a helper.

4.5.3 Activating/deactivating the main fuse

Activating the main fuse

1) Push the reset lvever, which is at an angle into the notch until it engages (see Fig. 5/6, item 1).

2) The main fuse is activated (see Fig. 5). The internal power supply is connected and activated.

Deactivating the main fuse

1) M@NNOC@KPNC=POOJIN@@DB{ÂÃxDO@H¿PIODGOC@M@N@OG@Q@MvDKNPK<O<I<IBG@{

2) The main fuse is deactivated (see Fig. 6). The internal power supply is disconnected.

5

6

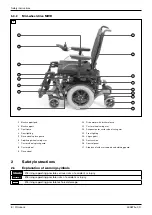

Summary of Contents for 490E75 Series

Page 1: ...490E75 0_C Service manual...

Page 38: ...Service work 490E75 0_C 38 Ottobock 57 58 59 60 61 62 63...

Page 41: ...Service work 490E75 0_C Ottobock 41 70 71 72 73 74 tt 75 76...

Page 55: ...Service work 490E75 0_C Ottobock 55 103 104 105 106 107 108 109 110...

Page 108: ...Service work 490E75 0_C 108 Ottobock 227 228 229 t 230 231 232...

Page 112: ...Service work 490E75 0_C 112 Ottobock 237 238 239 240 241...

Page 143: ...R Net wheelchair control 490E75 0_C Ottobock 143 Seat module pin assignment 287...

Page 161: ...490E75 0_C Ottobock 161...

Page 162: ...490E75 0_C 162 Ottobock...