Summary of Contents for Juditta B12

Page 2: ......

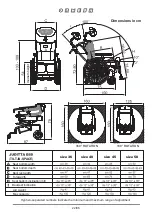

Page 12: ...10 86 ...

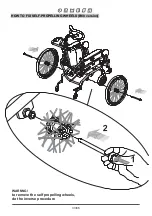

Page 27: ...ASSEMBLY BOTH SIDES 25 86 ...

Page 28: ...26 86 ...

Page 29: ...BOTH SIDES 27 86 ...

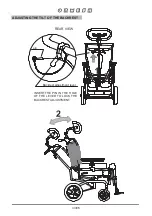

Page 30: ...CLAMPING LEVER INSERT THE HEADREST AND LOCK IT WITH THE CLAMPING LEVER 28 86 ...

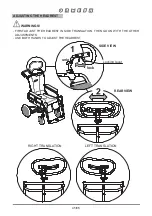

Page 41: ...REMOVING THE LEGRESTS 1 PRESS THE LOCK BUTTON 2 REMOVE THE LEGREST Lock button 39 86 ...

Page 43: ...TURNING THE CALF RESTS 41 86 ...

Page 45: ...ADJUSTING THE HEIGHT OF THE ARMRESTS Locking lever FRONT VIEW Unlock Lock Locking lever 43 86 ...

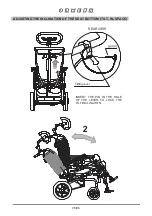

Page 53: ...TILT ADJUSTMENT OF THE PUSH HANDLE BUTTON 51 86 ...

Page 61: ...ADJUSTING THE TILT OF THE TABLE VIEW FROM BELOW unlocked lever locked lever 59 86 ...

Page 63: ...ABDUCTION BLOCK 834 WARNING TIGHTEN THE KNOB WELL 61 86 ...

Page 65: ...B UNLOCKING the footrest lock LOCKING LEVER C OPERATING the footrest lock LOCKING LEVER 63 86 ...

Page 66: ...CALF REST 916 1 REMOVE THE KNEE PADS 64 86 ...

Page 67: ...2 FIX THE CALF REST 916 Adjust the depth by loosening the velcro 65 86 ...

Page 69: ...REMOVABLE TABLE COVER 896 VIEW FROM BELOW OF THE TABLE 67 86 ...

Page 71: ...IV POLE 933 B30 and B12 version 69 86 ...

Page 72: ...70 86 ...

Page 74: ...Strap Strap Strap 72 86 ...

Page 77: ...SET OF HAND BRAKES 905 B60 version Strap cable control doubler 75 86 ...

Page 78: ...Strap Strap Strap 76 86 ...

Page 79: ...77 86 ...

Page 80: ...cable lock cable cable control internal view 78 86 ...

Page 81: ...Hand brake lever sheath doupler B60 wheel with drum brake 79 86 ...

Page 89: ......

Page 90: ......

Page 91: ......