63

VC_GB

.f

m

OPTIMUM

M A S C H I N E N - G E R M A N Y

®

5

Cutting speeds

5.1

Selecting the cutting speed

The variety of factors makes it impossible to present universal indications about the

"correct“ cutting speed.

Tables with reference values about cutting speeds to be set must be evaluated with utmost

caution since they only apply for very particular cases. The reference values without cooling (no

best values) which are indicated in AWF documents are highly recommended. Furthermore, the

tables of reference values of the manufacturers of cutting materials should be evaluated e.g. for

hard metal cutting materials the indications of the company Friedrich Krupp Widia-Fabrik,

Essen applies.

V

c60

is the cutting speed at 60 min. service life, V

c240

according for 240 min. service life. Select

V

c60

for simple, easily replaceable lathe tools; V

c240

for simple tool sets depending on one

another; V

c480

for complicated tool sets where the tool change requires more time due to the

dependencies on one another and the accuracies of the cutting insert. The same

considerations apply with regard to maintenance of the tools.

It generally applies: High cutting speeds result in low-time chipping, little cutting speeds result in

cost-efficient chipping.

5.2

Influences on the cutting speed

v

c

= Cutting speed in [ m/min]

t

= Service life in [min]

The service life

t

is the period of time in minutes during which the cutting insert performs cutting

tasks until it is necessary to re-sharpen it. It is of utmost commercial importance. For the same

material

t

is smaller the higher you select the value

v

c

e.g. only a few minutes at

v

c

= 2000 m/

min. Different materials require different

v

c

for the same

t

. All considerations of this type

require that the other cutting conditions are maintained constant

(material, tool and setting conditions). If only one of these condition changes it is also neces-

sary to change

v

c

in order to obtain the same

t

. Therefore, only cutting speed tables are rea-

sonable which show all relevant cutting conditions.

5.3

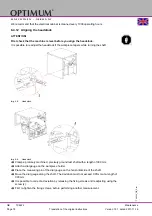

Example for the determination of the required speed on your lathe

The necessary speed is depending on the diameter of the workpiece, of the material to be

machined, of the turning tool, as well as of the setting of the turning tool (cutting material) to the

workpiece.

Material to be turned: St37

Cutting material (turning tool): Hard metal

Setting angle [k

r

] of the turning tool to the workpiece: 90°

selected infeed [f]: about 0.16mm/rev

Target value of the cutting speed [

v

c

] according to the table: 180 meters per minute

Diameter [d] of your workpiece: 60mm = 0.06m [meters]

Speed

Set the speed on you lathe below the calculated speed.

n =

V

c

π

x d

=

180m

min x 3,14 x 0,06m

= 955 min

-1