Safety

Version 1.0.1 dated 2017-11-16

Page 15

Translation of the original instructions

TX6222

GB

T

X

6222

_GB

_1.

fm

OPTIMUM

M A S C H I N E N - G E R M A N Y

®

Turn the knob to the right to unlock and release the emergency stop button.

CAUTION!

Only press the emergency-stop button in a genuine emergency. Do not use the

emergency stop button to stop the machine during normal operation.

By activating the emergency stop, the drive controls are shut off and the DC brake activated.

1.9.3

Protective cover of the headstock

WARNING!

Only remove the protective cover when the main switch of the lathe is turned off and

secured by a padlock.

1.9.4

Protective covers of drive

DANGER!

The machine may only be started back up when all safety covers have been installed and

screwed on tightly.

The machine bed of the lathe is equipped with permanently installed safety covers. The screws

are properly connected with the covers and therefore can not be lost.

1.9.5

Lathe chuck protection with position switch

The lathe is equipped with a lathe chuck protection. The lathe can only be switched on if the

lathe chuck protection is closed.

1.9.6

Chip guard shield

Polycarbonate inspection windows, which have a safety-critical protective function in respect of

flying parts, must be visually inspected at regular intervals by responsible personnel provided

by the customer in order to guarantee the operational safety of the milling machine.

Polycarbonate viewing panes are subject to an ageing process and are classified as wear

parts.

The aging of polycarbonate windows can not be detected by visual inspection. It is therefore

necessary to replace the polycarbonate windows after a certain time.

Prolonged exposure from polycarbonate windows to cutting fluids can lead to accelerated age-

ing, i.e. deterioration of the mechanical properties (brittleness). Coolant vapours, detergents,

greases and oils or other corrosive substances from the operator side can also lead to a deteri-

oration of the polycarbonate windows. The result is a reduced retention capability of the poly-

carbonate viewing pane against chips and potentially flying parts.

1.9.7

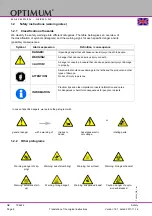

Prohibition, warning and mandatory signs

INFORMATION

All warning and mandatory signs must be legible. They must be checked regularly.

1.10

Safety check

Check the lathe at least once per shift. Inform the person responsible immediately of any dam-

age, defects or changes in the operating function.

Check all safety devices

at the beginning of each shift (with the machine stopped),

once a week (with the machine in operation),

after all maintenance and repair work.