Version 1.2.3 - 2021-11-02

83

Translation of original instruction

EN

sa

w

-band

-speed

_gene

ral-

inf

o_GB

.f

m

4.14

General information concerning saw bands

In order to achieve an optimum service life with a new saw band, it is necessary to run-in the

saw band carefully.

The excessively sharp cutting edges of the saw teeth of a new saw blade are sensitive against

small splinters coming off.

It is recommended to start sawing with up to 50% of the standard cutting pressure and only

increase the cutting pressure to standard level after about 10 to 15 minutes of cutting period

respectively 300 to 500 cm² of cut edge.

4.14.1 Spacing

The toothing indicates the number of teeth on one Inch (25,4mm).

General rule: The shorter the cutting length, the finer the toothing, the larger the cutting width,

the rougher the toothing to be used.

For an optimum performance of the cutting operation, apart from the steel quality, the number

of teeth as well as the shaping of the cutting edge is essential.

The geometric shape of the cutting edge and of the tooth root surface is depending on the

material to be cut and essentially influences the cutting behaviour of the metal band saw. We

recommend you four shapes of teeth to fulfil your cutting requirements:

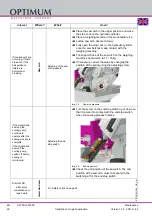

Full-length tooth

Effective cutting angle 0°: Full fillet radius tooth root surface. Universally applicable from little to

middle cross sections, tubes, plates, profile cuts.

Special tooth for gaps

Effective cutting angle 0°: Little addendum of tooth, plane tooth root surface. Recommended for

the cutting of rough material of larger cross sections, such as for instance bronze, brass,

zinc,aluminium cast, rough plastics.

Throat claw

Positive effective cutting angle: With full fillet radius tooth root surface. Advantageous for cutting

of oversized material, i.e. non-ferrous metals, steels with low carbon content, materials with

large cross sections, metal materials which are susceptible to cold-work hardening when cut-

ting.

Combined tooth

Toothing with 0° (N), positive (Plus) or extremely positive (Super Plus) effective cutting angle:

Permanently repeating tooth groups whose teeth within a group have different tooth pitch and

are therewith higher. The interfering oscillations are being reduced with a positive result on the

noise level, the quality of the cut surface and the tool life. The field of application of this toothing

is universal from layer and bundle cut up to the large cross sections of the different metal mate-

rials.