2-4

Pre-Installation Requirements

FiberPoint Structured Wiring Enclosure Installation Guide

Form 361015-0001A

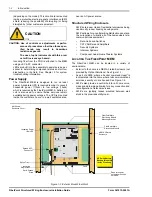

WARNING

1106

WARNING: This device does not incorporate a primary

protector. If off premises coax or telephone

cable lengths exceed 140 feet (42.7 meters)

a listed primary protector is required per

the National Electric Code.

•

When routing optic fibers, be careful to avoid bending

fibers beyond the manufacturer recommended 1”

(2.54 cm) bend radius. Exceeding the bend radius can

cause excess attenuation and possibly break the fiber.

•

Verify all optical power levels before connections are

made. If excessive loss is noted, the use of an optical

time domain reflectometer (OTDR) may be required.

•

Clean the fiber ends before making any connections.

2031

NOTICE

NOTICE: A Class I laser product is used in this equip-

ment. Use an optical power meter to identify

any active fiber. Never assume laser power

is turned off or that the fiber is disconnected

at the other end.

A protective cap or hood must be placed

over any radiating bulkhead receptacle or

optical fiber connector.

•

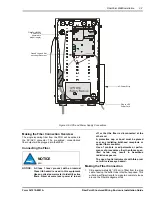

The electronics can be sensitive to electrostatic

discharge. Use of a static wrist strap is required when

handling the FiberPoint Electronics Module.

•

The FiberPoint Electronics Module relies on a quality

earth ground in order to process signals properly.

Make sure you follow all applicable local codes for

grounding.

•

For subscribers using data services, remember that all

data wiring done internally to the home is true CAT5 in

design.

•

Fiber Optic Drop Cables (or simply drop cables)

entering the FiberPoint Electronics Module from

underground must be protected. We recommend the

use of a riser tube for protecting the drop cable. Refer

to Form 360029-0001 for specifications on riser pipe.

•

The UPS must be installed indoors in a protected

environment that has adequate airflow.

W

HAT

’

S

N

EEDED

FOR

I

NSTALLATION

Every installation needs the following components for a

successful installation:

NOTE: Check the contents of each box carefully as

you receive it. Components may not be

located where you might expect them due to

certain items being tested immediately before

shipment.

•

(1) FiberPoint Structured Wiring Enclosure Bracket

•

Ground Terminal

•

Nut and washer for attaching ground terminal

The above items are pre-assembled

•

One of four Electronics Modules (consistent with

model ordered):

•

Part number MOD-FP-502 (2 Line POTS)

•

Part number MOD-FP-504 (4 Line POTS)

•

Part number MOD-FP-522 (2 POTS plus analog

video)

•

Part number MOD-FP-524 (4 POTS plus analog

video)

•

All-in-One Local power supply converter module and

Back-up UPS

•

DC Power Cord

T

OOLS

R

EQUIRED

In order to install the FiberPoint, the following tools are

necessary:

•

1/8” Drill (for drilling the bracket mounting holes).

•

Drill Bits appropriate for wall anchors or fasteners of

choice.

•

7/16” nut driver for securing ground strap and MOD-

FP-502/504/522/524.

•

Wire strippers.

•

Coaxial connector stripper and crimper.

•

Flat head screwdriver (ground lug).

•

Fiber Splicing Tools.

•

Fusion Splicer for fiber optic cable.

•

Carpenter’s level.

•

Optical Time Domain Reflectometer calibrated for

1310 and 1550nm output.

A

DDITIONAL

S

UPPLIES

N

EEDED

You may need the following additional supplies. See inside

front cover of this manual for contact information on any of

the following specialty items.

•

(4) # 6 x 1/2” Pan Head Thread Cutting Screws

•

Silicone sealant (for sealing entry/exit points - outdoor

applications only).

•

Electrical tape (for sealing buffer tube ends or wires

that are not used).

•

Cotton swabs (for applying silicone sealant).

•

Assorted tie wraps (for securing cabling, etc.)

•

Fiber Splice Tray

•

Tip & Ring Connectors

•

Additional RJ-11 Jumpers (MOD-FP-504, 524)

•

F-type coax cable (from CATV out port to inside

subscribers home).

•

(1) 60” p/n 12-219 Hi-cap riser pipe (outdoor

applications only).

•

TexWipe™ Alco pad for fiber cleaning (TX806).

•

Texwipe™ cloth for fiber cleaning (TX304).

•

SC/APC connectors (for fiber).