40

Operating the System

AS7200 User Manual - OPEX Corporation

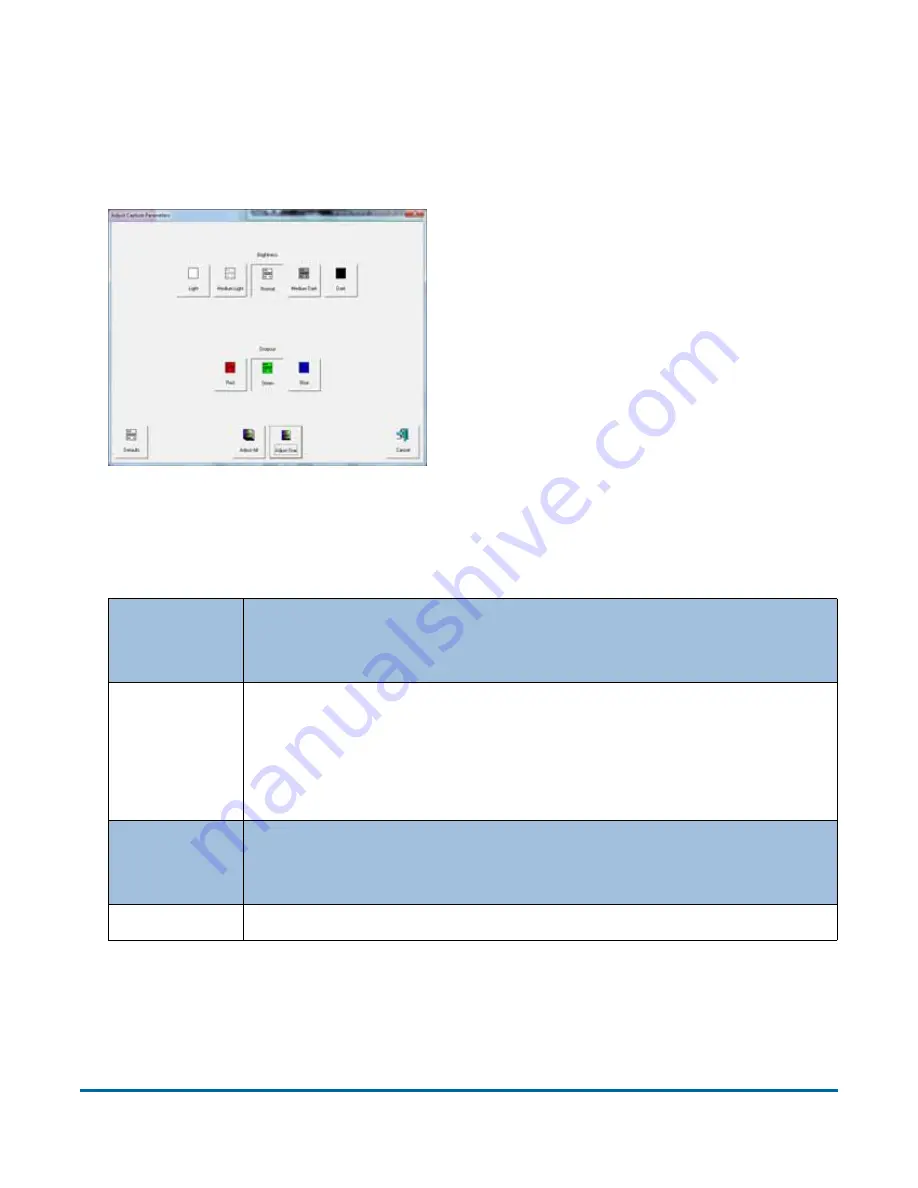

Adjusting image quality

Fine-tune the quality of the document images by pressing

A

DJUST

on the Run

screen. The Adjust Capture Parameters screen will appear, where you can

modify the brightness and dropout colors for the images.

Table 1 describes the Adjust Capture Parameters screen buttons.

Table 1: Adjust Capture Parameters screen buttons

Brightness

Adjust the brightness of the document images from

L

IGHT

to

D

ARK

. Press a button to adjust the brightness. The default is

N

ORMAL

.

Dropout

Remove a dropout color (

R

ED

,

G

REEN

,

B

LUE

, or

W

HITE

) from the

document image. The color you select will appear as white.

The default is

W

HITE

.

Note:

To use this feature, the documents must be printed with

a specific dropout color.

Adjust All/

Adjust One

Select

A

DJUST

A

LL

to apply these changes to all the documents

in the current job, or

A

DJUST

O

NE

to make the adjustments only

to the next document scanned.

Defaults

Return to the default capture parameters.