Chapter 1: Quattro ePLC Robot Quick Setup

1. Remove all lag bolts from the robot base mounting pads.

2. Wrap slings around the robot base. See the preceding figure for two methods.

3. Lift the robot and position it directly over or under the frame mounting pads.

For above lift/bottom mount or below lift/top mount, you will have to rotate the robot so

that its mounting pads clear the frame mounting pads.

4. Refer to the following table for mounting bolt torques.

Using a Forklift:

1. Remove all lag bolts from the robot base mounting pads.

2. Lift the robot and position it directly over or under the frame mounting pads.

Use a padded board as a support under the robot base.

If you want to mount to the top of the frame’s mounting pads, you will have to twist

the robot so that its mounting pads clear the frame mounting pads, and you can raise

them above the frame.

3. Refer to the table that follows for mounting bolt torques.

Install Mounting Hardware

NOTE:

When mounting the robot, note the following:

1. Place split lock, then flat washers on the bolts.

Bolts are M16 x 2.0 if threaded into the robot base mounting tabs.

Bolts are M12 or ½ in. if going through the robot base mounting tabs into nuts.

NOTE:

When M16 x 2.0 bolts are used, the bolt must engage at least 24 mm into

the threads of the base mounting pad.

2. Insert the bolts through the holes in the frame mounting pads and into the threaded

holes in the robot base mounting pads.

If using through-bolts, insert the bolts through the holes in both the mounting pads and

through the threaded holes in the robot base mounting pads into nuts.

3. Tighten the mounting hardware to the specifications listed in the following table.

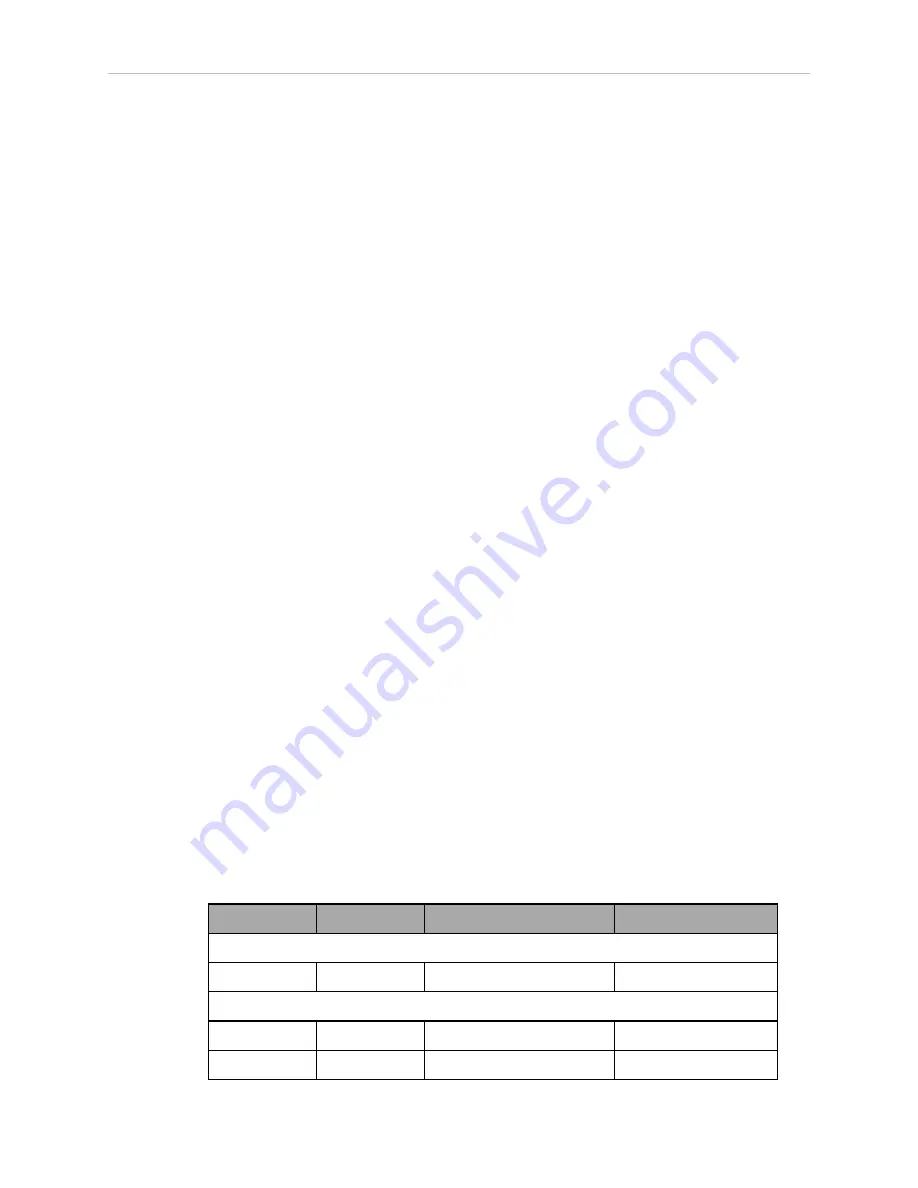

Table 1-1. Mounting Bolt Torque Specifications

Standard

Size

Minimum Specification

Torque

Threaded into base (aluminum):

Metric

M16 x 2.0

ISO Property Class 5.8

98 N·m (74 ft-lb)

Using base mounting pad hole as through-hole:

Metric

M12

ISO Property Class 9.8

100 N·m (75 ft-lb)

SAE

½ in.

100 N·m (75 ft-lb)

Quattro ePLC650/800 Quick Setup Guide, 13588-000 Rev D

Page 7 of 16

Summary of Contents for Quattro 650H

Page 1: ...I598 E 01 Quick Setup Guide Quattro 650H 650HS 800H 800HS ePLC...

Page 14: ......

Page 15: ......