Configur

Configur

Configur

Configur

Configura

aa

a

ation

tion

tion

tion

tion

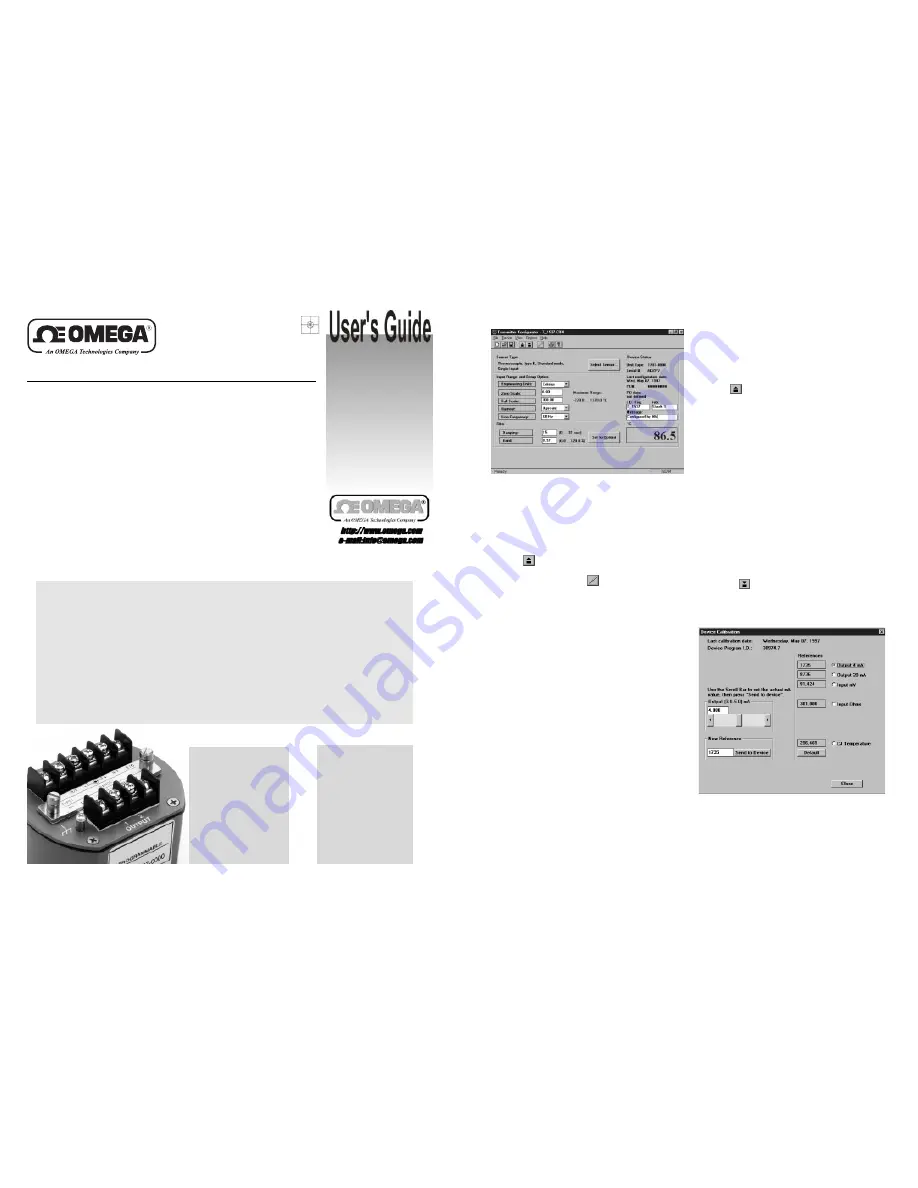

Configuration may be performed with a transmitter on-line or off-line.

When a transmitter is on-line, the upload and download icons will be

distinctly black. If no transmitter is on-line, those icons will be grey.

1. Upload

Current configuration from the transmitter

2. Configure

•

If the current “Sensor Type” does not match the application, click

on the “Sensor Selection” box then select the appropriate “tab” at the

top of the “Input Sensor Selection” screen.

•

Make one selection from the “Input Connection” and “Type” boxes

(if offered) for the selected sensor type. Leave the “Mode” as “Stan-

dard” or the “Transfer Function” as “Linear” for now. Click the “OK”

button to return to the Configuration Screen.

•

Select the Engineering Units (from the pull down menu), enter the

“Zero Scale” and “Full Scale” values and the “Burnout” mode

(transmitter to go above full scale or below zero scale upon input

failure).

•

Click the "

Set to Optimal

" button to optimize the

transmitter's filtering.

3. Download

New configuration to the transmitter.

Calibr

Calibr

Calibr

Calibr

Calibra

aa

a

ation

tion

tion

tion

tion

To calibrate the transmitter, connect a 24VDC power supply, a 250

Ω

load

and multi-meter (in milliamp mode) in series to the transmitter's output.

1. Upload

2. Click on the Calibration Icon

3. Output Calibration:

Select "

Output 4mA

", enter the mA reading from

the meter into the dialog box and click "Send to Device." Repeat for 20mA

calibration.

4A.

Input Calibration Models XXXXX-X000

(e.g. TX787-0000):

Provide a precision 100.00mV source to the transmitter, select "

Input mV

"

on the Device Calibration screen, wait for the on-screen display to settle,

then click "Send to Device." Repeat the procedure, substituting a 300.00

Ω

input (4-wire connection) and selecting "

Input Ohms.

"

4B. Input Calibration Models XXXXX-X001

(e.g. TX787-0001):

Provide a precision 300.00mV source to the transmitter, select "

Input

mV

" on the Device Calibration screen, wait for the on-screen display to

settle, then click "Send to Device." Repeat procedure, substituting a 15.00

Volt input and selecting "

Input Volts

", and substituting a 50mA input,

selecting "

Input mA.

" Note that the input terminals are different for each of

the signal levels.

5.

To calibrate the cold junction compensation reference, select

“Tem-

perature,”

enter the nominal ambient temperature in the dialog box, set

the input simulation type to match the input simulator (i.e., type J thermo-

couple), verify that the simulator is set to the proper value, then click “Send

to Device.”

6. Click “Close.”

A message in the lower left corner of the screen will

indicate the progress of the download and finally that the download has

been successfully completed.

1. Install the Configuration and Calibration software

Run “setup.exe” on the distribution diskette and follow the on-screen instructions.

Note: the software contained on the distribution diskette runs under Windows 95 and Windows NT.

If you are running Windows v3.1, contact Omega Engineering.

2. Connect the Communications Adapter to the computer and transmitter.

3. Identify the serial port to which the Adapter is connected.

Select “Options” from the menu bar, then click “Communications” and select the correct COMM port from the pull-

down menu. Note that if you change the serial port you must exit the software and restart

it with the correct setting.

4. Configure the transmitter.

What you will need:

Calibration

• PC

• Communications Adapter

• Transmitter

• Multimeter

• 24VDC power supply

Configuration

• PC

• Communications Adapter

• Transmitter

Intr

Intr

Intr

Intr

Intr oduction

oduction

oduction

oduction

oduction

Models TX787 and TX788 are microprocessor-based 2-wire transmitters that feature high accuracy and

high long-term stability. Setting the new standard in ease of setup, these transmitters feature

PC-Only™

configuration technology. The unique Communications Adapter provides a fully isolated serial interface

and power source,

allowing the transmitter to be configured with a “

PC-Only

” - no external power

supply, calibrator or meter is required!

Quic

Quic

Quic

Quic

Quick Star

k Star

k Star

k Star

k Star ttttt

Before beginning the process of setting up the transmitter, it is important to understand the difference between

calibration

and

configuration

. The transmitter’s precision references (4 and 20 milliamps out; resistance,

voltage and current as appropriate; and a thermal reference) are

calibrated

at the factory and may be adjusted

later if necessary.

Configuration

is the process of defining the sensor type and range in engineering units.

Configuration

is performed by connecting the transmitter to a PC and running the configuration software.

Because the Communications Adapter provides power to the transmitter’s microprocessor, it is not necessary to

provide any external power to the transmitter in order to configure it.

PC-Only Programmable Transmitter