d-Color MF4003/MF3303

J BILLING SETTING/ENHANCED SECURITY/DEBUG SETTINGS > 2. ENHANCED

SECURITY

J-28

NOTE

▪ It is displayed when Backup Settings is enabled.

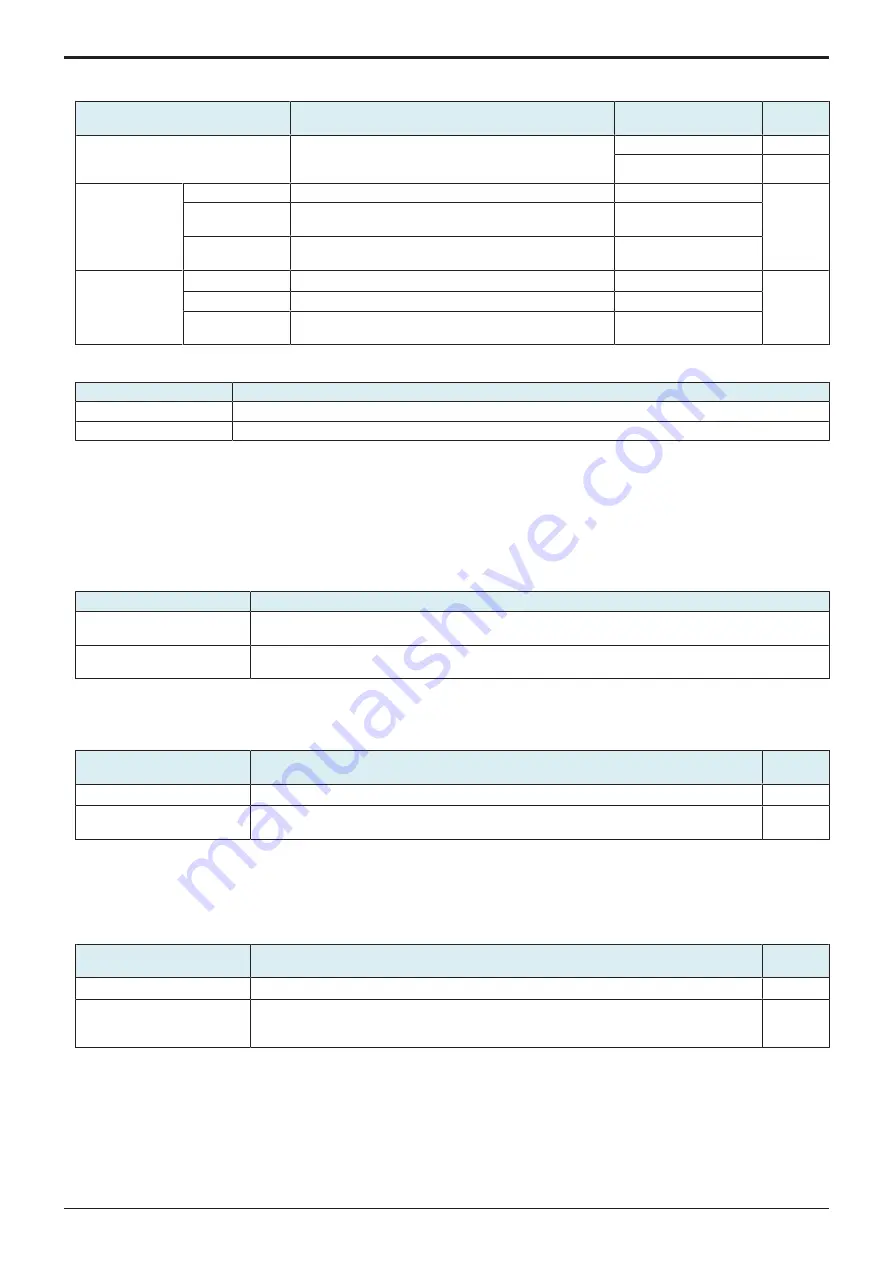

Setting item

Contents

Setting value

Default

setting

Enable Settings

To set whether to execute auto backup.

• When “Yes” is selected, configure the following

settings.

ON

Disable

○

Full Backup

Interval of day(s)

Select the backup as Interval of day(s).

1 to 30 days

-

Weekly frequency

Select the backup as Weekly frequency.

Sun, Mon, Tue, Wed, Thu,

Fri, Sat

Backup time

To setting a time to back up.

Hour: 00 - 23

Minute: 00 - 59

Diff. Backup

Disable

Select not to backup Diff. backup.

-

-

Time Setting

Select the backup period by time setting.

1 to 48 hours

Time Setting

Select the backup period by time setting.

Hour: 00 - 23

Minute: 00 - 59

<Backup reservation>

• To select the backup reservation.

Setting item

Contents

Full Backup

Select to make backup Full backup.

Diff. Backup

Select to make backup Diff. backup.

NOTE

To select the backup reservation and touch [Fix].

<Backup history>

• To make a confirmation of the date and time when the final backup is completed successfully.

• Up to 100 backup logs can be displayed in the order from the latest backup.

(2) Restore from Server

Restore Mode Select

• Select the restore method.

Setting item

Contents

Restore from Server

Select to make restore from the server.

Set “Setting when selecting restore from the server”.

Restore from Server 2

Select to make restore from the server as restore 2.

Set “Setting when selecting restore from the server 2”.

Setting when selecting restore from the server

<Restore setting>

• To specify a location from where restore data is to be downloaded.

• Select a server and press “Start” to start restoring.

Setting item

Contents

Default

setting

Acquire from backup

Execute restore from a location other than the server specified in Backup Settings.

○

Edit Restore path

Execute restore other than from a location other than the server specified in Backup Settings.

• When Edit Restore path is selected, enter WebDAV setting and Encryption Password.

<Restore result>

• To display the final date of restore.

Setting when selecting restore from the server 2

<Restore setting>

• To specify a location from where restore data is to be downloaded.

• Select machine, restore data and restore target from [Restore Data Select] and press “Start” to start restoring.

Setting item

Contents

Default

setting

Acquire from Backup

Execute restore from a location other than the server specified in Backup Settings.

○

Edit Restore path

Execute restore other than from a location other than the server specified in Backup Settings.

• When Edit Restore path is selected, enter Download Protocol and SMB setting, or HTTP

Setting and Encryption Password.

<Restore history>

• Restore history is displayed.

• Insert USB memory, touch the start key and save the restore result details in the USB memory.

2.12.2 Server Function

• Use MFP as backup server (WebDAV server).

Service Manual

Y119930-3

Summary of Contents for d-Color MF 4003

Page 1: ...Multifunction Digital Copier d Color MF4003 MF3303 Service Manual Version 2 0 Code Y119930 3 ...

Page 48: ...This page is intentionally left blank ...

Page 54: ...This page is intentionally left blank ...

Page 70: ...This page is intentionally left blank ...

Page 76: ...This page is intentionally left blank ...

Page 98: ...This page is intentionally left blank ...

Page 216: ...This page is intentionally left blank ...

Page 354: ...This page is intentionally left blank ...

Page 388: ...This page is intentionally left blank ...

Page 398: ...This page is intentionally left blank ...

Page 570: ...This page is intentionally left blank ...

Page 572: ...This page is intentionally left blank ...

Page 574: ...This page is intentionally left blank ...