5238-E P-112

SECTION 7 FIXED CYCLES

[Programming format]

LE33013R0300900090002

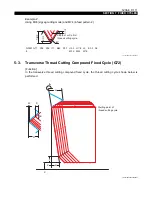

5-4.

M Code Specifying Thread Cutting Mode and Infeed Pattern

The tool angle, B, thread height, H, depth of cut in first thread cutting cycle, D, and stock removal,

W, are indicated below for thread cutting in the longitudinal direction and in the transverse direction.

LE33013R0300900100001

X

: X coordinate of end point of thread

Z

: Z dimension of final thread cutting cycle

A

: Taper angle

K

: Distance between starting point and end point for taper thread

For taper thread, use either an A or K word.

B

: Infeed angle(0

°

x B < 180

°

; 0 if no B command is designated.)

D

: Depth of cut in the first thread cutting cycle

W : Finishing allowance

(No finishing cycle is performed if no W word is designated.)

H

: Thread height

L

: Chamfering distance in final thread cutting cycle

(Effective in the M23 mode; if no L word is designated in the M23 mode, L is assumed to be

the distance equivalent to one lead.)

E

: Lead variation per lead in cutting variable lead thread

(When no E word is specified, the control assumes E=0.)

F

: Thread lead (F/J if a J word specified.)

J

: Number of threads within a distance specified by F word

(When no J word is specified, the control assumes J=1.)

M

: Used to select thread cutting pattern and mode of infeed.

(For details, refer to "M Code Specifying Thread Cutting Mode and Infeed Pattern")

Q

: The number of threads for multi-thread thread cutting (refer to "Multi-thread Thread Cutting

Function in Compound Fixed Thread Cutting Cycle")

G72 X__ Z__ B__D__ W__H__L__E__F__J__M__Q__

{ }

K__

A__

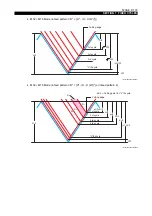

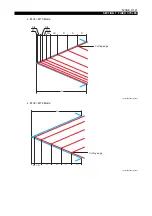

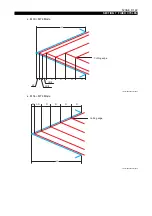

B : Tool angle

H : Thread height

D : Depth of cut in first thread cutting cycle

U(W) : Stock removal

B

D/2

U/2

H/2

Thread Cutting in Longitudinal Direction

W

D

H

B

Thread Cutting in Transverse Direction