5238-E P-97

SECTION 7 FIXED CYCLES

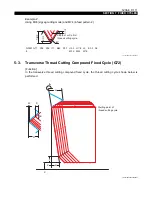

2.

Fixed Thread Cutting Cycles

For details on writing thread cutting programs, refer to "Precautions when Programming Thread

Cutting Cycles".

2-1.

Fixed Thread Cutting Cycle: Longitudinal (G31, G33)

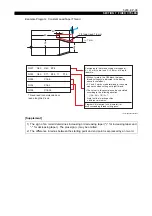

[Programming format]

LE33013R0300900030001

LE33013R0300900030002

A thread cutting cycle can be programmed in the same manner with G31 as with G33.

G33 : Fixed thread cutting cycle (longitudinal) command

G31 : Fixed thread cutting cycle command

X

: Thread diameter for each thread cutting cycle

Z

: Coordinate value of thread end point in Z-axis direction

F

: Thread lead (F/J if a J word is provided.)

I

: Difference in radius between start and end of taper

A

: Taper angle (Taper is specified by either an I or A word.)

E

: Z-axis shift amount of thread cutting starting point

(When no K word is specified, the control assumes K=0.)

L

: Chamfering distance

(When no L word is specified, the control assumes L=one lead at thread cutting start)

L word is effective in the thread chamfering ON (M23) mode.

J

: Number of threads within a distance specified by the F word

(When no J word is specified, the control assumes J=1.)

C

: Phase difference for multi-thread thread cutting

(when no C word is specified, the control assumes C=0.)

{ }

G33 X__ Z__ (E__) F__ (K__)(L__)(J__)(C__)

(G31)

A__

I __

Z

X

L

I

K

A

Starting point