24

Printing on reflective sheeting

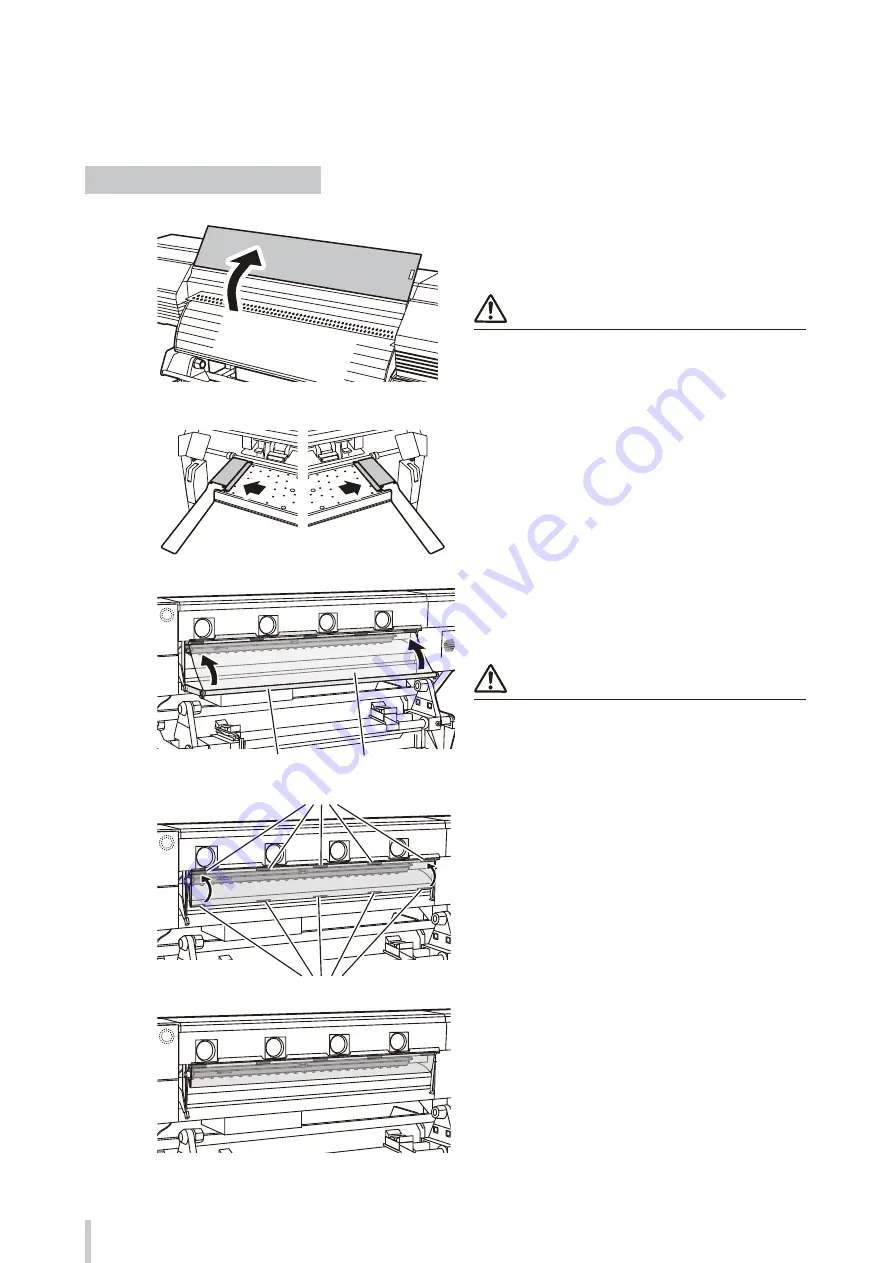

Loading the media on the printer

Procedure to load roll media

1

Open the front cover and place the right and

left edge guards at each extremity of the

platen. Close the front cover.

Notes

The media edge guards are put aside to avoid any

contacts with the roll ends when loading the media.

When using a media whose end is attached to the roll

tube with adhesive, this adhesive may adhere to the

paper guide or the platen. In this case, be sure to remove

all adhesive before loading the new media.

2

Pipe

Dust cover

Hook-and-loop fastener

Hook-and-loop fastener

< Supply side >

Close and fold the dust cover, and then attach

it with the hook-and-loop fasteners.

Notes

Hold the pipe with both hands when handling the dust

cover.

Pay attention not to catch your fingers when handling

the dust cover.

Do not move only one side of the dust cover, but close

both sides of the cover completely.

Summary of Contents for ColorPainter M-64S

Page 54: ...54 Printing on reflective sheeting...

Page 84: ...47260301EE Rev4...