MCH60

Nuvair

Page 20

www.Nuvair.com

•

Oil Level Sight Gauge and Oil Pressure Gauge

•

Automatic Condensate Drains

•

Loadless Start

•

Low Oil Shutdown Switch

•

Final Stage Head

•

High Temp Switch set at 350°F

•

(4) CAN-35 Filtration Towers

o

(3) Dyer Filter Elements

o

(1) Triplex Filter Element

o

130,000 cu ft

•

Aluminum frame with isolation vibration mounts

Lubricant:

•

Nuvair 455

TM

Food Grade Lubricant (standard)

•

Nuvair 751

TM

Diester Based Lubricant (optional)

6.0 Compressor Specifications

Ambient room temperature should never exceed 113

°

F (45

°

C) during operation of the Compressor

System. Operation at higher temperatures may lead to system damage and malfunction.

6.1 Unpacking and Installation

•

Please read all information supplied before physically installing the Compressor System.

•

Unpack the system and remove from the pallet. Visually inspect the system to make sure there has

been no damage during shipping. If damaged, please call Nuvair to file a damage report. Please take

photos and supply detailed information about the damage.

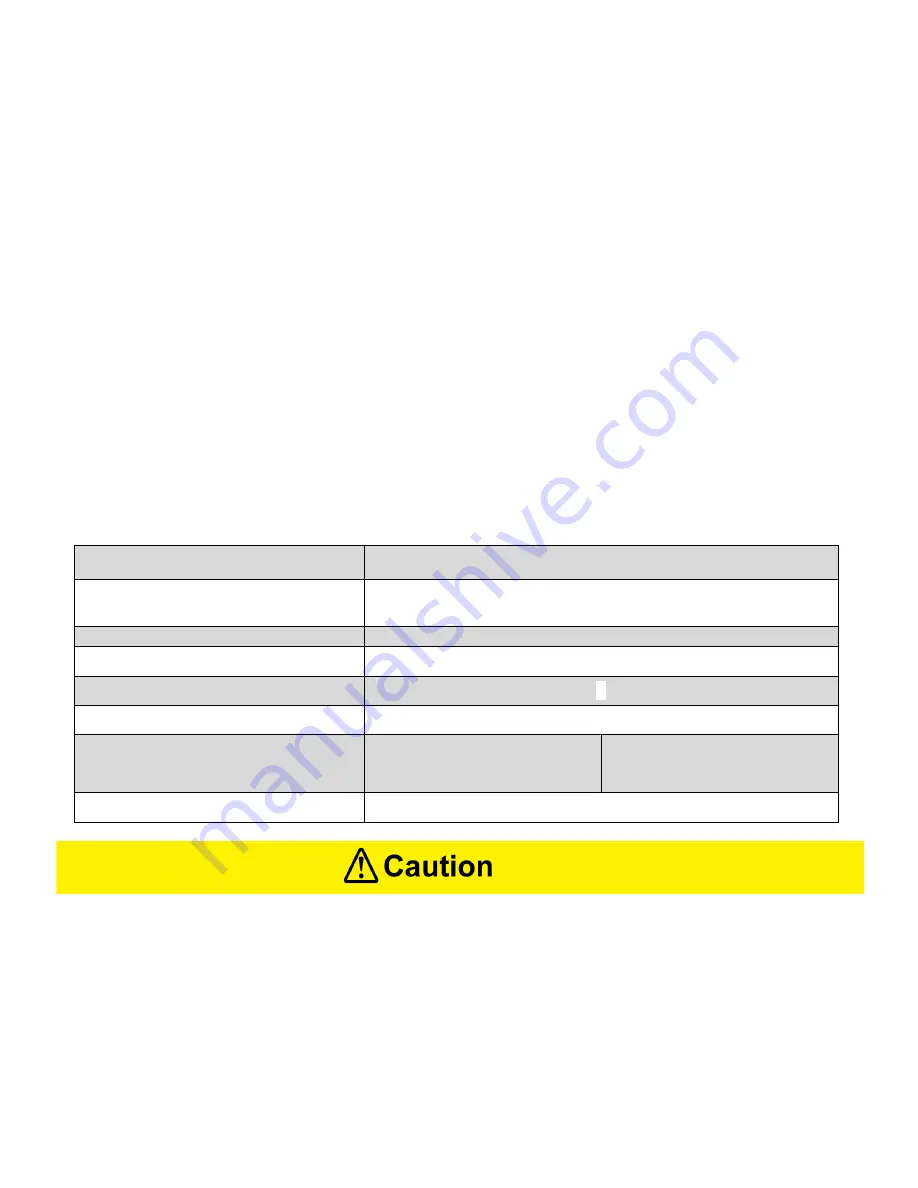

Compressor Models

Two (2) Coltri MCH30

Charging Rate

Filling an 80 cu ft tank from 500 psi

20.4 SCFM (577 L/min)

×

2

Total Charging Rate: 40.8 SCFM (1154 L/min)

Maximum Operating Pressure

6000 psi (414 bar)

Pumping Unit RPM

1100

Number of Stages

4

×

2

Lubrication

Pressure Lubrication, capacity 1.2 gal (4.5 L)

×

2

Oil Pressure

cold

routine use

minimum pressure

58 psi (4 bar)

21.75 psi (1.5 bar)

14.5 psi (1 bar)

Air Quality

Grade E

Summary of Contents for MCH60

Page 1: ...Operation Manual MCH60...

Page 2: ...MCH60 Nuvair Page 1 www Nuvair com Notes...

Page 3: ...MCH60 Nuvair Page 2 www Nuvair com Notes...

Page 37: ...MCH60 Nuvair Page 36 www Nuvair com 19 0 Service Log Date Technician Name Service Performed...

Page 41: ...MCH60 Nuvair Page 40 www Nuvair com Notes...