12

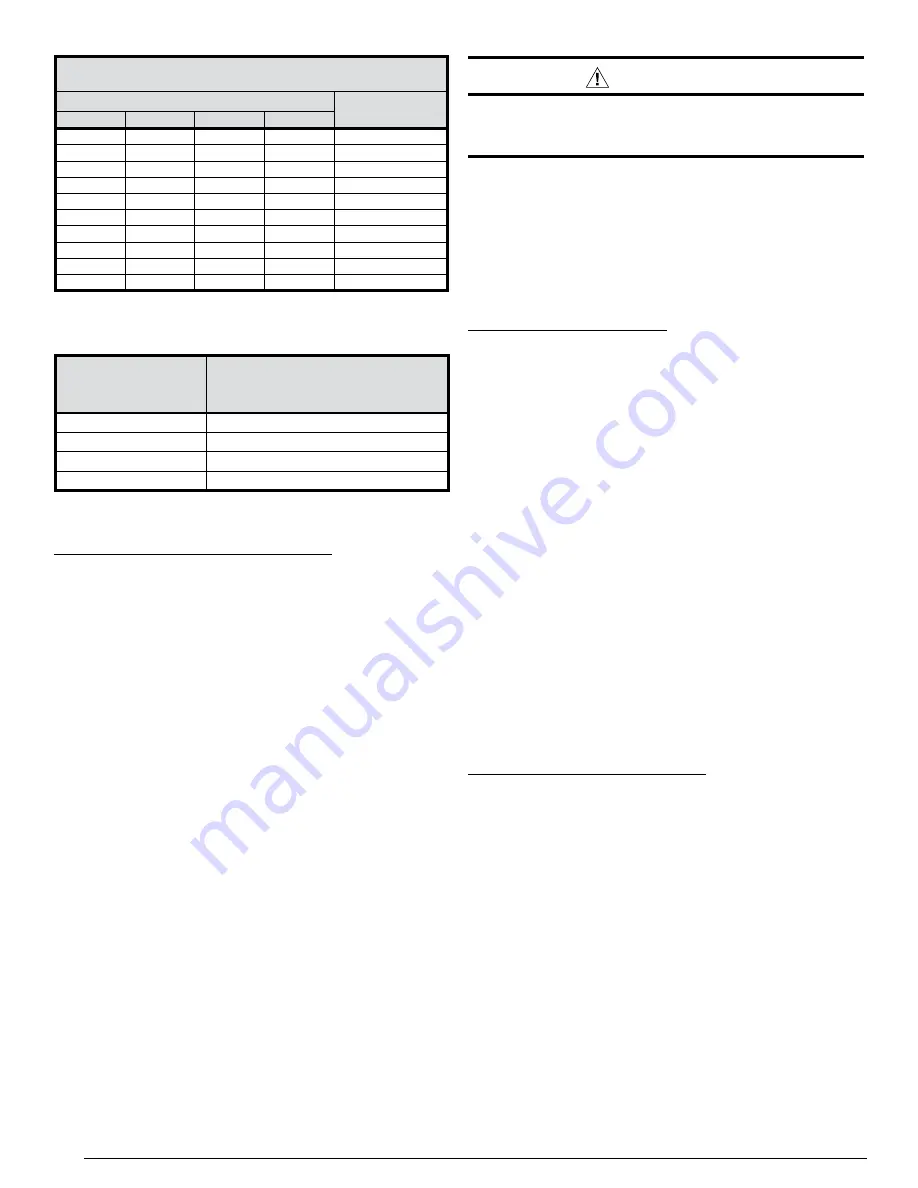

Table 3. Copper Wire Size

COPPER WIRE SIZE — AWG

(1% VOLTAGE DROP)

SUPPLY WIRE LENGTH-FEET

SUPPLY CIRCUIT

AMPACITY

200

150

100

50

6

8

10

14

15

4

6

8

12

20

4

6

8

10

25

4

4

6

10

30

3

4

6

8

35

3

4

6

8

40

2

3

4

6

45

2

3

4

6

50

2

3

4

6

55

1

2

3

4

60

NOTE:

Wire Size based on N.E.C. for 60° type copper conductors.

Table 4. Thermostat Wire Gauge

WIRE GAUGE

RECOMMENDED MAXIMUM

WIRE LENGTH (FT) FROM UNIT

TO THERMOSTAT

22

45

20

70

18

115

16

180

Checking Heat Anticipator Settings

• Add the current draw of the system components.

OR

• Measure the current flow on the thermostat

R

-

W

circuit

after the circulating blower motor has started. Set the heat

anticipator according to the thermostat manufacturer’s

instructions for heat anticipator settings.

Heating Configurations

This furnace is factory configured for two stage gas heating

operation with a two stage heating thermostat. Connect the low

voltage thermostat

White

&

Brown

wires to

W1

&

W2

, between

the unit low voltage terminal board and thermostat sub-base.

To operate with a single stage heat thermostat, only connect

the low voltage thermostat

White

wire between

W1

on the unit

low voltage terminal board and thermostat sub-base. Reposition

the automatic heat staging jumper located on the ignition control

module from NONE to 5 or 10 for the desired delay in minutes

before the gas furnace will automatically move to high heat

operation. See

NOTE:

When low fire on the gas valve is energized, the furnace

operates in low fire mode at a lower blower speed and the timer

begins its delay function. If the room thermostat is not satisfied

before the timer activates, the furnace will stage to high fire.

The inducer motor and blower will ramp to a higher speed until

the thermostat is satisfied.

Configuring the Variable Speed Blower

The variable speed blower has been designed to give the

installer maximum flexibility for optimizing system performance,

efficiency, and comfort. It is equipped with a microprocessor-

controlled variable speed motor that is pre-programmed to

deliver optimum airflow in a variety of conditions and system

configurations. Because the blower can be configured in many

ways, it is important to read and follow all instructions carefully.

CAUTION:

To avoid personal injury or property damage, make

certain that the motor leads cannot come into contact

with any uninsulated metal components of the unit.

Before operation, the variable speed blower must be configured

to match the unit with the system, climatic conditions, and

other system options. With the blower installed and configured

properly, the furnace will gradually change speed in response

to changes in system variables such as thermostat settings,

duct static, filters, etc. The variable speed blower is configured

by setting the heat, cool, and adjust jumpers located on the

ignition control board as described below. See

.

Selecting Cooling Airflow

The cooling airflow is selected by setting the Cool and Adjust

jumpers on the ignition control board.

lists the recommended airflow values (CFM) and selector

tap settings for each nominal system capacity. All airflows

for other modes of operation (except secondary gas heat)

are determined by this basic setting. For maximum capacity,

generally, a selection at or near the top of the CFM range for

that nominal capacity is best.

NOTES:

• The CFM values listed in

are not dependent on

duct static pressure. The motor automatically compensates

(within the limits of the motor) for changes in duct static

pressure.

• If coil icing occurs, the basic cooling airflow selected may

be too low. Verify the selected setting is within the range

shown in

and the system is properly charged. If

icing continues, raise the selected airflow to the next higher

tap.

• For maximum dehumidification and energy efficiency, select

an airflow near the middle or bottom of the CFM range for

that nominal capacity.

• The 2-stage cooling feature of the unit requires modulating

the airflow. The unit will automatically adjust the airflow to

the appropriate rate when the unit capacity changes.

Selecting Gas Heating Airflow

The heating airflow is selected by setting the heat jumper to

the desired tap (A,B,C, or D) located on the ignition control

board. Refer to

rise based on the furnace’s nominal efficiency and firing input.

Follow across the table row to find the tap setting and nominal

air-flow. Verify the selected rise is within the specification shown

on the furnace rating label.

Optional Humidistat

An optional humidistat may be installed in the return air duct

for humidity control (when needed), maximum system capacity

and energy efficiency. The humidistat senses when humidity in

the return air stream is above a preset level and sends a signal

to the motor to reduce airflow. This allows more moisture to be

removed until the humidity level drops.

NOTE:

The indoor blower

motor of this packaged unit is pre-programmed for humidistat

operation. Remove the

Red

jumper wire between the

R

and

DEHUM

terminals on the ignition control board.

If installing a humidistat, install it in the return air duct as

directed in the installation instructions included with the kit.