Safety

1-3

2000 Nordson Corporation

All rights reserved

Issued 7/00

S1EN–03–[SF–Powder]–6

Know where emergency stop buttons, shutoff valves, and fire

extinguishers are located. If a fire starts in a spray booth,

immediately shut off the spray system and exhaust fans.

Clean, maintain, test, and repair equipment according to the

instructions in your equipment documentation.

Use only replacement parts that are designed for use with original

equipment. Contact your Nordson representative for parts

information and advice.

All work conducted inside the spray booth or within 1 m (3 ft) of booth

openings is considered within a Class 2, Division 1 or 2 Hazardous

location and must comply with NFPA 33, NFPA 70 (NEC articles 500,

502, and 516), and NFPA 77, latest conditions.

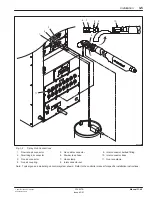

All electrically conductive objects in the spray areas shall be

electrically connected to ground with a resistance of not more than 1

megohm as measured with an instrument that applies at least 500

volts to the circuit being evaluated.

Equipment to be grounded includes, but is not limited to, the floor of

the spray area, operator’s platform, hoppers, photoeye supports, and

metal blow-off nozzles. Personnel working in the spray area must be

grounded.

There is a possible ignition potential from the charged human body.

Personnel standing on a painted surface, such as the operator

platform, or wearing non-conductive shoes, are not grounded.

Personnel must wear shoes with conductive soles or use a ground

strap to maintain a connection to ground when working with or around

electrostatic equipment.

Operators must maintain skin-to-metal contact between their hand

and the gun handle to prevent shocks while operating manual

electrostatic spray guns. If gloves must be worn, cut away the palm

or fingers, wear electrically conductive gloves, or wear a grounding

strap connected to the gun handle or other true earth ground.

7. Grounding

Summary of Contents for Sure Coat Series

Page 8: ...Safety 1 0 2000 Nordson Corporation All rights reserved Issued 7 00 S1EN 03 SF Powder 6 ...

Page 28: ...Operation 4 0 2001 Nordson Corporation All rights reserved 334 627B Issued 3 01 Manual 31 46 ...

Page 34: ...Operation 4 6 2001 Nordson Corporation All rights reserved 334 627B Issued 3 01 Manual 31 46 ...

Page 46: ...Repair 6 0 2001 Nordson Corporation All rights reserved 334 627B Issued 3 01 Manual 31 46 ...

Page 56: ...Parts 7 0 2001 Nordson Corporation All rights reserved 334 627B Issued 3 01 Manual 31 46 ...

Page 66: ......