KX driver tool unit

7

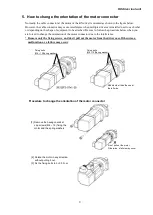

4. Cable connection

Connect a motor cable and an encoder cable to

the tool unit as shown in the right figure. (For

connection at the controller, refer to a separate

document “Driver controller SD550 Instruction

manual ”.)

Be sure to connect the motor cable first, and then

connect the encoder cable. Fix each connector

with 2 M2 pan head machine screws (supplied

with the connector). Tighten the screws securely

to a torque of 0.15 N·m and confirm the

connector is not loose. Since each connector

uses packing, don’t lose it when

attaching/detaching the connector.

Example of fixing a cable

Fix a cable with a binding band etc. as shown in

the right figure.

(Note 1) Be sure to connect a motor cable first,

and then connect an encoder cable.

(Note 2) When fixing a cable, be sure to hold

the connector.

(Note 3) Bending radius of the motor cable

should be not less than 50 mm.

(Note 4) Prevent the binding band and the cable

etc. from applying an external force to

the encoder cover.

Otherwise, the encoder may fail.

(Note 5) In the case of the binding example 1,

be sure to fix the cables in such a way

that the encoder cable comes between

the motor cable and the connector.

Pan head machine screws M2

Tightened to 0.15 N·m.

[1] Motor cable

Must be connected first.

[2] Encoder cable

Must be connected after the motor cable is connected.

* Be careful not to lose the rubber packing.

Encoder cover

Binding band

Motor cable

Binding example 1

Encoder cover

Encoder cable

Motor cable

Binding band

Encoder cable

Binding example 2

Keep as large a distance

as possible.

*

Summary of Contents for KX Series

Page 2: ......

Page 30: ... Machinery Division http www nittoseiko co jp ...