Address: Room1121 Linqiao Piazza, Ningbo City,315010, China Tel:+86(574) 27861829 27861849 Fax:+86(574)87264906

E-mail: [email protected]

Http://www.

brand.COM

DSW

Ningbo DSW International Co.,Ltd.

O

F

F

O

N

M

E

M

O

R

Y

O

F

F

O

N

S

T

A

T

U

S

L

E

D

Test

LED

Alarm

LED

Status

LED

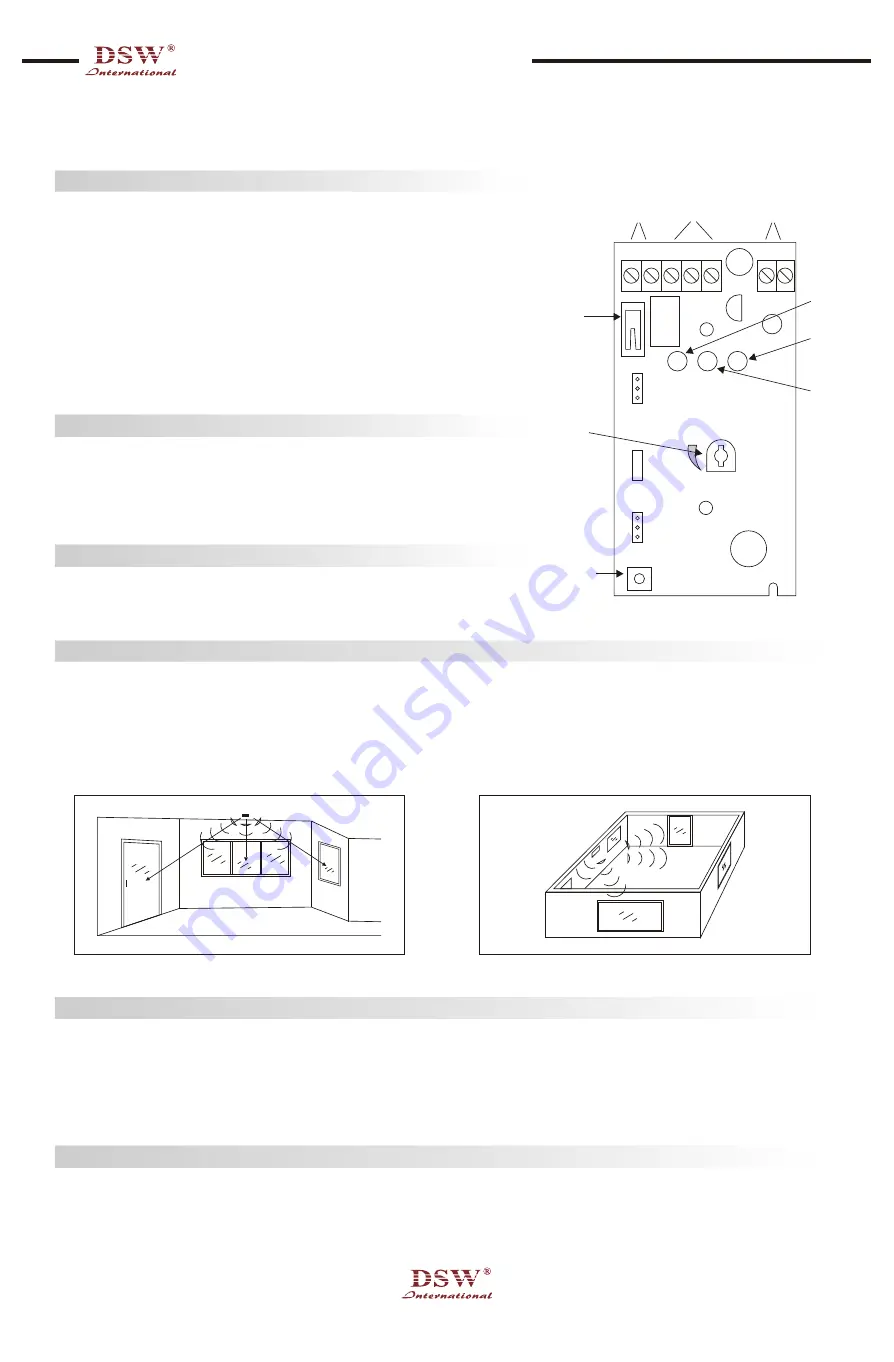

TEST STATUS ALARM

TAMP C NC NO

+ -

Tamper

Output

Relay Output

Power

S

E

N

S

IT

IV

IT

Y

P

O

S

O

N

IC

P

S

-3

7

2

TEST

Test

Mode

SW

Sensitivity

VR

Tamper

SW

MIC

Figure 1

PS-372 Digital Glass Break Detector

Installation Manual

Thank you for selecting the PS-372 glass break detector, which is designed for

professional .security applications, with advanced techniques. Please follow the

instructions m this manual carefully to optimize use of your detector, which has

been 100% quality control tested to ensure proper operation and unit durability.

The PS-372 is a microprocessor-based glass break detector utilizing dual fi-

equency analysis to detect the common sounds of shattering glass and acoustical

shock.when a window is broken. It can analyze the frequency and wave shape of

the sound received by a condenser microphone and compare with the real glass

break data inside .its database and determine whether it is an alarm .signal. The

detector's sensitivity can be set manually so that a good balance point is reached

according to the environment condition. "The alarm LED indicating lamp on the

detector may be programmed for memory or auto reset with a configuration

jumper inside the detector.(See Fig.1). You have got PS-372, the most advanced

glass break detector available on to-day's security market.

The PS-372 will protect 3- 6mm plate glass and 6mm tempered and laminated

glass at a range of up to 8m. In order to achieve the best result, the detector

should be firmly fixed on a surface. Room acoustics will also affect the range of a

glass break detector, It is better that the acoustic environment, such as furniture

layout, during testing is same as the normal situation. It is very important that the

detection range is verified using the PS-373 tester.

1. Driven by software, 8/12 bits microprocessor, controlled DSP(8MHz)

2. High fi'equency and sound pressure detection

3. Digital RF1/EMI filtering, extremely high immunity.

4. Manual sensitivity settings to avoid false alarm.

Mount the PS-372 on the ceiling or wall with the most open and direct acoustic path to the protected glass. (See Fig 2 &3). Keep an

open field between the glass break detector and points of entry (no partitions, walls, etc. between the detector and the protected glass.)

While the PS-372 may be mounted on any wall or ceiling, a 40% reduction in range is expected when mounting on the same wall as the

glass. Drapes and window coverings will affect the detection range. USe the PS-373 Glassbreak Simulator behind window coverings to

test properly. Do not mount the detector closer than 1.2m to door bells, air conditioners, air compressors, large fans, steam or air vents,

or any other sources that tend to generate noise interference. If, for any reason, the unit does not enter the Normal mode of operation

immediately following its power up sequence (see STATUS INDICATORS), verify that the TestMode Jumper/Switch is in the OFF

position and reset the device by de-powenng and reapplying power.

1. Remove the cover by pressing the opening pin(l) on the side of the detector.

2. Run the wire through one of the holes at the back or side openings of the case.

3. Connect the terminals.

4. Mount the detector in its location with a screw inserted into screw holes (2) and (3).

5. Setting of sensitivity

6. Replace the cover.

7. Test the detector.

MOUNTING LOCATION

Figure 3 (mounted on wall)

Figure 2 (mounted on ceiling)

FEATURES

INTRODUCTION

INSTALLATION

APPLICATIONS

WIRING TERMINATION

-Wiring connection of the terminals is as follows:

TAMP: Connect to 24 hour zone or tamper zone of alarm control panel.

RELAY OUTPUT: NC,C is normal closed output, NO,C is nom3al opened output.

POWER SUPPLY: Connect to DC12V auxiliary output of alarm control panel.