Engine System

24

Service Manual – PBU Propane Floor Burnisher

Fuel System

The PBU fuel system functionally consists of the propane tank, pressure regulator, carburetor, mechanical

governor, and operator throttle position selector The fuel (propane) is stored in the tank as a liquid, but

is dispensed into the fuel system as a gas The fuel pressure in the tank is much too high to be used by the

engine The pressure regulator reduces the pressure of the gas before it is delivered to the carburetor

The pressure regulator does more than just reduce the pressure, however It also meters the amount of fuel

being delivered to the engine based on the demand for fuel by the engine When the engine isn’t calling for

fuel, the diaphragm (valve) inside the pressure regulator stays closed, and no fuel is delivered When the

engine causes a small vacuum in the carburetor during the intake cycle, the diaphragm is opened and fuel

begins to flow. The amount of fuel flowing is proportional to the amount of vacuum from the carburetor.

In a sense, the pressure regulator is like a mechanical amplifier. A small amount of vacuum at the outlet is

able to control the large pressure at the inlet (the tank). The adjustments to the regulator fine tune the ratio

of this small vacuum to the control of the high pressure

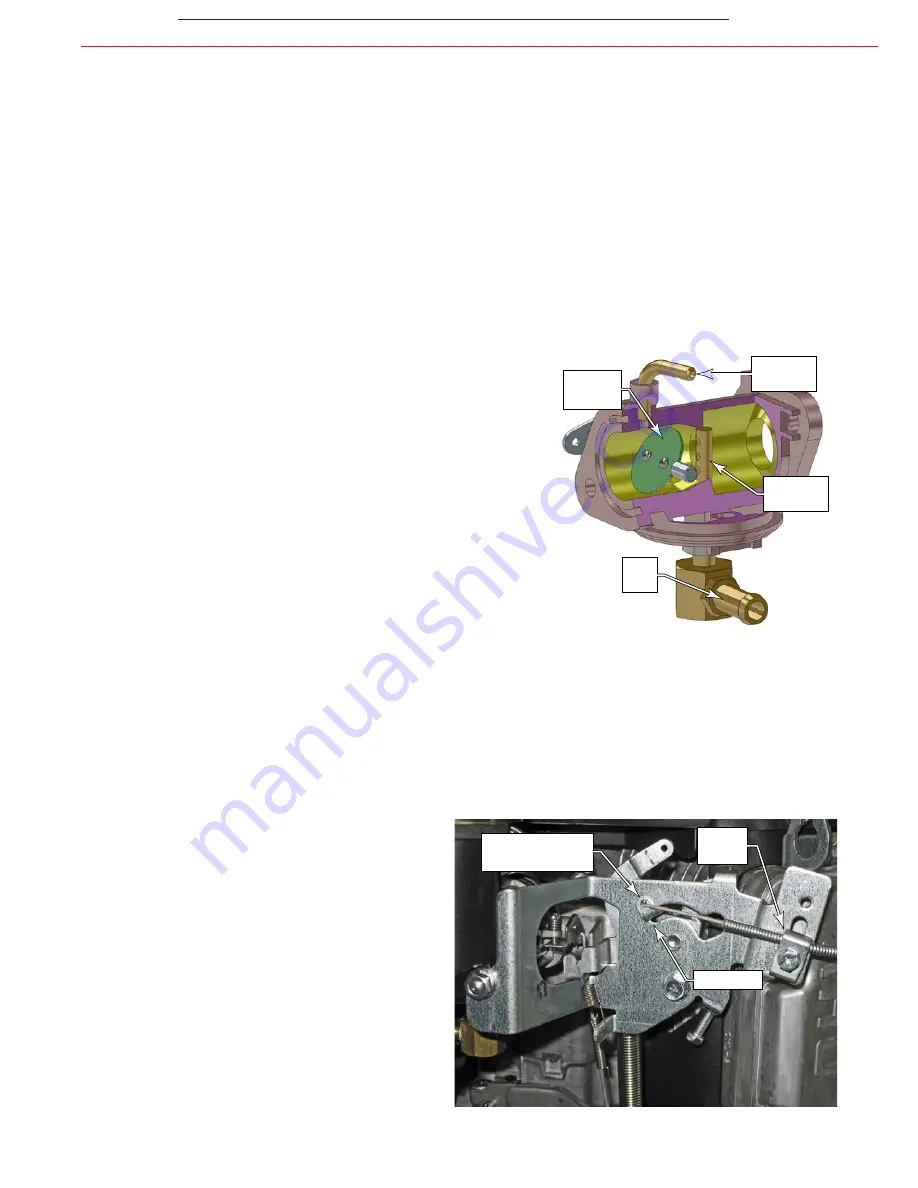

The carburetor mixes the fuel and air in the proper proportion for

combustion by the engine A small metering jet in the carburetor

controls the ratio of fuel to air, and a butterfly valve controls the

total volume of fuel/air that is permitted to enter the engine The

position of the butterfly valve is controlled by the mechanical

governor

The governor is inside the engine and operates on centrifugal force

The faster the engine turns, the more the governor tries to close

the carburetor’s butterfly valve. Conversely, a spring connected to

the operator’s throttle position lever tries to pull the butterfly valve

open When these two forces are balanced, the engine will run at

constant speed even when the load on the engine changes When

the engine gets loaded, the speed drops and the governor doesn’t

pull the butterfly closed as hard, causing the valve to open more,

and more fuel/air to enter the engine

To prevent fuel from flowing to the engine when the engine isn’t running, there are two fuel lockouts. The

first is an electric valve that opens only when the ignition is turned on. The second is a vacuum lockout that

prevents fuel from flowing if there is no vacuum present at the carburetor.

Throttle Cable Position

The most common reasons for performing this adjustment are if the throttle cable has been replaced, or

if the cable clamp has loosened over time This procedure adjusts the effective length of the cable for full

throttle movement

1 Place the throttle selector into the Slow-position,

but do not force it if it doesn’t go all the way into

position

2 Loosen the cable clamping screw

3 Make sure that both the Throttle Selector

and the Throttle Link Arm are in their lowest

position, and then retighten the cable clamping

screw

4 Make sure the Throttle Selector can be moved

through its full range without causing the cable

to slip under the clamp

Butterfly

Valve

Metering

Jet

Vacuum

Lockout

Fuel

Inlet

Cable

Clamp

Throttle Position

Link Arm

Low Limit

New & Reconditioned Equipment & Parts- www.southeasternequipment.net

New & Reconditioned Equipment - www.southeasternequipment.net