6. Packet Structures

NOTE

Some soft starters do not support some functions.

The following functions are only available with Digistart D3 soft starters:

parameter management, dual motor control, digital inputs, jog, current measurement in

amperes, power information, warnings.

6.1 Ensuring Safe and Successful Control

Data written to the Profinet Module will remain in its registers until the data is overwritten or the module is

reinitialised. The Profinet Module will not transfer successive duplicate commands to the soft starter.

NOTE

If the soft starter is started via fieldbus communications but stopped via the keypad or a remote

input, an identical start command cannot be used to restart the starter.

In order to operate safely and successfully in an environment where the soft starter may also be

controlled via the keypad or the remote inputs (as well as via fieldbus communications), a control

command should be immediately followed by a status query to confirm the command has been actioned.

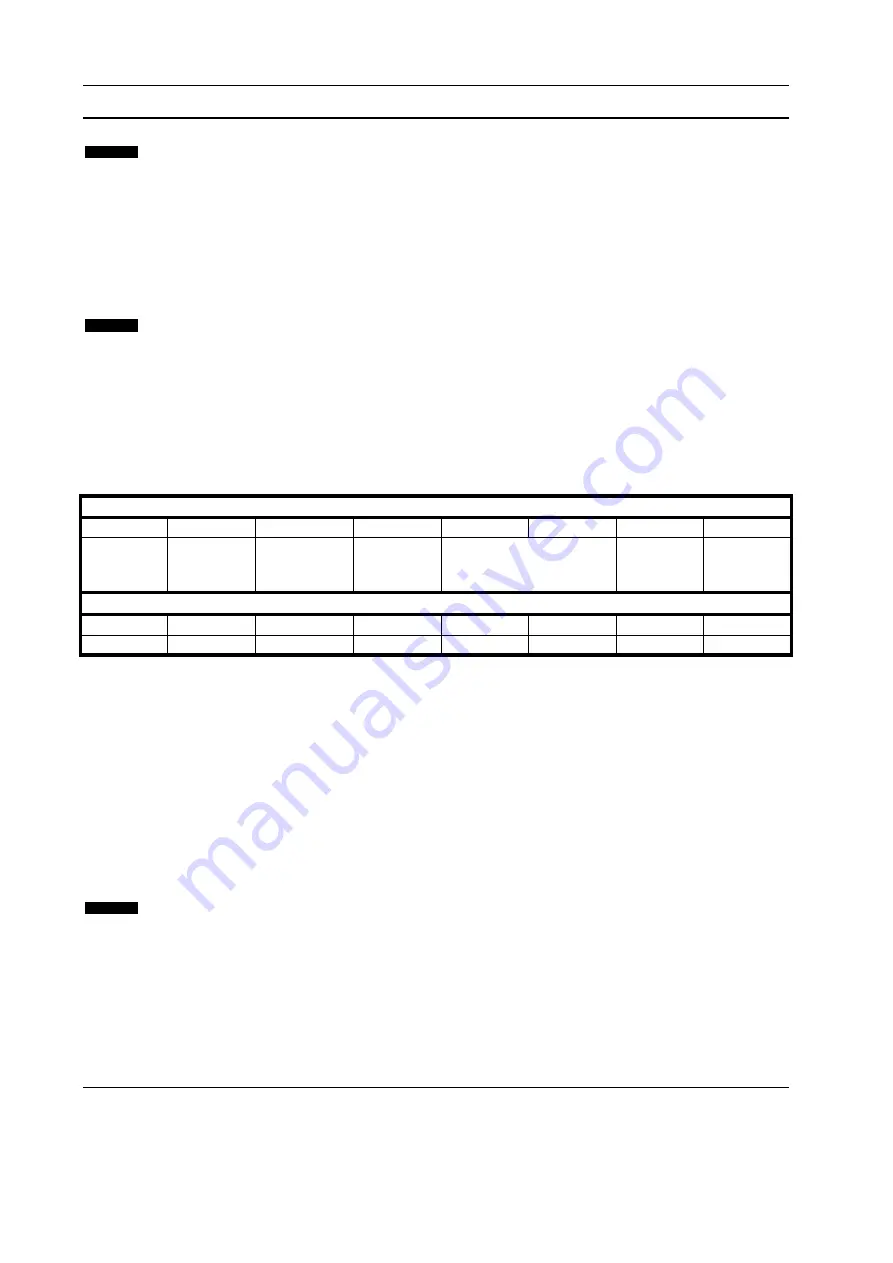

6.2 Control Commands (Write Only)

Use the following structures to send a control command to the soft starter:

Table 6-1 Control I/O data structure

Byte 0

Bit 7

Bit 6

Bit 5

Bit 4

Bit 3

Bit 2

Bit 1

Bit 0

Reserved

Reserved

Reserved

Quick stop

(coast to

stop)

Motor set

Reserved

Reserved

Byte 1

Bit 7

Bit 6

Bit 5

Bit 4

Bit 3

Bit 2

Bit 1

Bit 0

Reserved

Reserved

Reserved

Reserved

Reset

Reserved

Reserved

Fwd run

6.2.1 Motor Set Bits

Selects which parameter set to use when starting:

0 = selected from soft starter remote input (programmable input must be set to 'Motor Set Select')

1 = soft starter primary motor set (ensure soft starter programmable input is not set to 'Motor Set Select')

2 = soft starter secondary motor set (ensure soft starter programmable input is not set to 'Motor Set

Select')

3 =

Reserved

6.2.2 Quick Stop Bit

When Fwd run bit changes from 1 to 0:

0 = stop action will be a soft stop (as selected on the soft starter).

1 = stop action will be a quick stop (ie coast to stop).

NOTE

The Quick stop bit must be set to 0 before the soft starter can perform a start.

6.2.3 Forward Run

When Forward run changes from 0 to 1, the soft starter will start according to the Motor set setting.

When Forward run changes from 1 to 0, the soft starter will stop according to the Quick stop setting.

Profinet Module: User Guide

11

Issue: B

www.nidec.com