APPENDIX C CONNECTORS FOR TARGET CONNECTION

45

C.2 Cautions on Handling Connectors

(1) When taking connectors out of the case, remove the sponge while holding the main unit.

(2) When soldering the NQPACK144SD to the target system, cover the HQPACK144SD to protect it against

splashing flux.

Recommended soldering conditions… Reflow

: 240

°

C, 20 sec. max.

Partial heating : 240

°

C, 10 sec. max. (per pin row)

(3) Check for abnormal conditions such as resin burr or bent pins before setting a device to the NQPACK144SD.

Moreover, check that the hold pins of the HQPACK144SD are not broken or bent before setting HQPACK144SD.

If there are broken or bent pins, fix them with a thin, flat plate such as a blade.

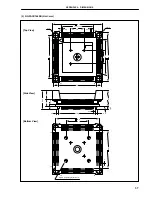

(4) When securing the YQPACK144SD (connector for emulator connection) or HQPACK144SD to the

NQPACK144SD with screws, tighten the four screws temporarily with the provided screwdriver or driver with

torque gauge, then tighten the screws in a crisscross pattern (with 0.054 N

⋅

m max. torque).

Excessive tightening of only one screw may diminish conductivity.

If the conductivity is diminished after screw-tightening, stop tightening, remove the screws and check whether the

NQPACK144SD is stained and make sure the device pins are parallel.

(5) Device pins do not have high strength. Repeatedly connecting to the NQPACK144SD may cause pins to bend.

When setting a device to the NQPACK144SD, check and adjust bent pins.

Summary of Contents for IE-703102-MC-EM1

Page 2: ...2 MEMO ...

Page 10: ...10 MEMO ...

Page 24: ...24 MEMO ...

Page 26: ...26 MEMO ...

Page 34: ...34 MEMO ...

Page 40: ...40 MEMO ...

Page 46: ...46 MEMO ...

Page 48: ...48 MEMO ...