TRUE ROUND FIRE & FIRE/SMOKE DAMPER INSTALLATION,

OPERATION & MAINTENANCE INSTRUCTIONS

IOM - TRUE ROUND FIRE & FIRE/SMOKE DAMPERS - 1016

NCA MANUFACTURING INC. • 1985 CARROLL ST. • CLEARWATER, FL 33765 • 727.441.2651 • www.ncamfg.com

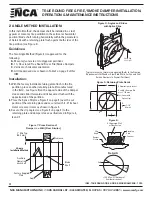

1 ANGLE METHOD INSTALLATION:

Guidelines:

The One Angle Method (Figure 8) is approved for the

following:

A.

Masonry/concrete walls and steel stud/gypsum walls

B.

1 ½ Hour rated True Round Fire or Fire/Smoke Dampers

C.

Vertical orientation

D.

All UL approved sizes shown in Table 1 on page 2 of this IOM

In this install method, the damper may also be installed in a

steel stud/gypsum, or masonry wall, in a vertical position

(blade running horizontally within the parameters of Detail

B), with a retaining plate on one side of the wall.

Installation:

A.

With the factory installed retaining plate flush to the fire

wall, place 8 screws equal distance around the perimeter

of the retaining plate per the following:

1.

For steel studs use #10 sheet metal fasteners

long enough to penetrate the metal stud by 1/2” (13mm)

minimum

2.

For masonry walls use #10 x 1-1/4” (32mm) masonry

screws

B.

Refer to Figure 9 for placement of screws. Fasteners

shall be placed in each corner and halfway between the

corners as shown.

C.

Place the Splice Clip (see Figure 3 on page 3) over the cut

portion of the retaining plate and secure it with 4 - #10 sheet

metal screws or rivets as shown in Figure 4.

D.

Secure the clip angles (see Figure 3 on page 3) to the

retaining plate and damper sleeve as illustrated in Figure 8,

10 and 11.

Figure 8: Angle on 1 Side

with Splice Clips

Typical masonry or metal stud opening. (Refer to the Framing

Requirements for Wood or Steel Stud Walls For Fire and

Fire/Smoke Dampers In Drywall Partitions)

Cutline on

retaining

plate

(Cover with

Splice Clip)

Figure 9: Retaining Plate Detail

Blade

Shaft

Auxiliary

Operating

Jackshaft

1” Min. Typ.

3

5

(25.4 mm)

4

OPTION 2

6B

Figure 11: Cross Section of

Damper in Wall

5

Clip Angle

Fastener

Damper

Sleeve

Retaining

Plate

Fastener

UL Approved Wall

or Floor Design

Figure 10

Axle

30˚

+/- 30˚ Max. Off Horizontal

(in either direction)

Detail B

1 Angle

Installation Method

Splice Clip

(see Fig. 3)