TRUE ROUND FIRE & FIRE/SMOKE DAMPER INSTALLATION,

OPERATION & MAINTENANCE INSTRUCTIONS

IOM - TRUE ROUND FIRE & FIRE/SMOKE DAMPERS - 1016

NCA MANUFACTURING INC. • 1985 CARROLL ST. • CLEARWATER, FL 33765 • 727.441.2651 • www.ncamfg.com

3

FIRE & FIRE/SMOKE DAMPER SLEEVES & MOUNTING CLIPS:

Damper Sleeves:

All true round fire and fire/smoke dampers must have an

integral sleeve (see Figure 1).

Guidelines:

1.

Sleeves must be of the SAME GAUGE or heavier than

the duct to which it is attached if one of the UL approved

breakaway connections is used (see seperate “UL App-

roved Breakaway Duct Connections” supplement).

2.

Gauges shall conform to SMACNA or ASHRAE duct

standards.

3.

Sleeves shall not extend beyond the fire barrier more

than 16” (406mm) on the operator side or 6” (152mm) on the

opposite side.

4.

The connecting duct shall terminate at the

integral sleeve and is connected by using either of the

following:

A.

Minimum of 3 - #10 sheet metal screws spaced equal

distance around the sleeve for 22” (559mm) and ~

smaller duct.

B.

Minimum of 5 - #10 sheet metal screws spaced equal

distance around the sleeve for greater than 22”

(559mm) duct.

C.

4” (101mm) drawband.

5.

Clearance between the damper sleeve and the round or

square wall opening shall be a minimum of 1/2” (13 mm)

and a maximum of 1” (25mm).

Note:

When installing the round damper into a square

opening, these clearances refer to the middle point of each

side of the square, not the corners.

6.

Damper will be factory supplied with one retaining plate

secured to the damper sleeve on the operator side of the

damper.

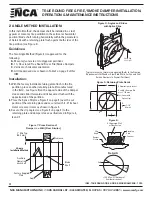

Mounting Clips:

A minimum of 4 equally spaced 20 gauge galvanized steel clip

angles (see Figure 3) shall be attached to both the integral

sleeve and the retaining plate (see Figures 1 and 2). The clip

angles shall be attached with 1/8” (3.2mm) rivets, #10 x

1/2” (12.7mm) steel metal screws, bolts or welds.

Note:

In metal stud/gypsum applications, the retaining plate

may be in front of or behind the gypsum, directly against the

metal studs.

1-1/2”

(38 mm)

Clip Angle Detail 20 Ga.

(1) Galv. Steel

1-1/2”

(38 mm)

1-1/2”

(38 mm)

Splice Clip Detail

1-1/2”

(38 mm)

Same length as

cut in damper/

retaining plates

Figure 1: Angles on 2 Sides

Figure 2: Angle on 1 Side

Figure 3: Mounting Clips

Typical stud or masonry opening. (Refer to the Framing Requirements for

Wood or Steel Stud Walls For Fire and Fire/Smoke

Dampers In Drywall Partitions)

Typical masonry or metal stud opening. (Refer to the Framing Requirements

for Wood or Steel Stud Walls For Fire and Fire/Smoke

Dampers In Drywall Partitions)

Splice Clip

(see Fig. 3)

Splice Clip

(see Fig. 3)