20 System Details

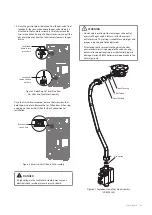

To measure the inlet gas pressure:

1. Shut off the manual gas valve on the gas supply line pipe.

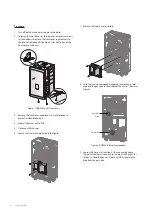

Gas Valve

Opened

Closed

2. Open a hot water tap. The boiler should turn on and the gas

in the gas supply line will be purged.

3. Leave the tap on until the boiler shuts down due to a lack of

gas supply, and then turn off the hot water tap.

4. Unfasten the two latches (at the top) and remove two

screws (at the bottom) to remove the front cover and gain

access to the internal components.

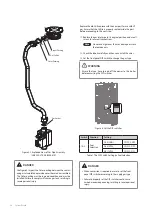

CAUTION

Ensure that no cables are in the way before folding down

the PCB assembly. If the assembly is stuck, do not force

it. Doing so may damage the cables and result in serious

malfunctions. Check again to ensure that no cables or any

other parts are in the way before you proceed.

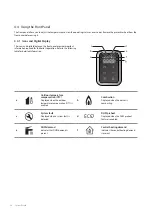

4.2 Measuring the Incoming Gas Pressure

WARNING

The boiler cannot function properly without sufficient inlet

gas pressure. Measuring the inlet gas pressure should be

performed by a licensed professional only.

Natural Gas Connection

●

The gas supply must comply to the current Gas Safety

(Installation and Use) Regulations, in accordance with BS 6891.

●

The nominal inlet working gas pressure measured at the

appliance should be 21 mbar +/- 2 mbar for Natural gas (G20).

Allowing for the acceptable pressure loss of 1 mbar across

the installation pipework, it can be assumed that a minimum

permitted operating pressure of 18 mbar will be delivered

to the inlet of the appliance. (Reference BS 6400-1 Clause 6.2

Pressure Absorption).

●

When tested at the gas valve, the pressure drop from the

meter to the gas valve must not be more than 4 mbar.

Propane Gas Connection (LPG)

●

For use with propane gas, the LPG conversion kit has to be

installed, see separate conversion instructions.

●

The LPG installation must comply to the current Gas Safety

(Installation and Use) Regulations, in accordance with BS 6891.

●

Installing of a LPG installation should only be done by a

registered LPG installer.

●

The tank must be provided with a high pressure regulator with

a minimum capacity of 24 kg/h to reduce the tank pressure

from 5 to 1.5 bar. The 1.5 bar high pressure gas line should

have a minimum diameter of 15 mm. In the high pressure gas

line a house pressure regulator must be installed.

●

When tested at the gas valve, the pressure drop from the

pressure regulator to the gas valve must not be more than

2.5 mbar.

●

Each gas appliance which is connected to the propane

installation must be provided with its own house pressure

regulator. The house pressure regulator is a third party part.

The house pressure regulator must have a minimum capacity

of 10 kg/h/37 mbar and a CE certification.

Summary of Contents for NCB300-28K

Page 3: ......

Page 4: ...Revisions 3 Version Description of changes Date 1 00 First issue September 7 2022 Revisions...

Page 106: ...Memo...

Page 107: ...Memo...

Page 108: ...Memo...