1. First remove fixture cover by unscrewing two bolts

holding cover to can.

2. Remove LED Brick Star reflector by unscrewing the

screws, holding reflector in place. See schematic on

adjacent page.

3. Using a knife, or very thin flat blade screwdriver,

remove reflector and set beside fixture.

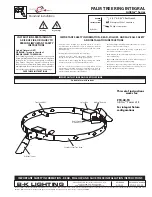

4. Select a mounting location for the LED Brick Star.

Fixture should be within reach of 120VAC power,

located 9 inches above the surface to be lit, and situ-

ated at the best location along the mounting surface

for the illumination task.

5. LED Brick Star may be used in any standard brick wall

in lieu of a brick. Make sure LED Brick Star is com-

pletely wired and inspected before wall is completed.

NOTE: Masonry wall installation warning adjacent

schematic, and corrosion warning on reverse side.

6. LED Brick Star has flanges that will allow the can

to be securely affixed to almost any surface with

the four mounting screws provided. Installations in

drywall will require a wood backing behind drywall.

Place can in hole (7-3/4” x 3-1/4” x 2-1/2”) and mark

the position of the four mounting screws. Reposi-

tion can in hole, and securely fasten the can to the

mounting surface by firmly tightening four mounting

screws.

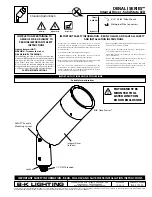

In the highly unlikely event of an LED module failure,

please follow the instructions listed below:

CAUTION!

If unit has recently been operating, glass

lens and LED module are hot! Turn off fixture and allow

it to cool for 15 minutes before relamping.

CAUTION!

Always turn off the main power, before

replacing the LED module.

NOTE:

Using a thin pair of gloves during this proce-

dure will eliminate fingerprints on glass lens and LED

module.

1. First remove fixture cover by unscrewing two bolts

holding cover to can.

2. Remove the reflector by unscrewing the screws

holding it in place.

3. Disconnect the LED module from 120V wires. Please

make sure that the 120V wires are not “hot”.

4. Remove the LED module by unscrewing the screws

holding it in place. Replace it with a new one. Tighten

screws just snug.

5. Re-connect the power wires to the LED module.

6. Replace the reflector by tightening the screws.

7. Replace fixture cover by fitting cover to can so gasket

seals and screwing in both cover bolts firmly.

WARNING!

If this fixture is to be placed in a masonry

or brick wall, you must use a Concrete Cap during can

installation to provide the proper void for the fixture

cover. Failure to use the Concrete Cap will almost

guarantee concrete or grout forming against fixture can

flange, and poor cover-to-can seal (see below). Poor

cover seal will allow water/moisture into fixture result-

ing in LED failure.

CAUTION!

Use RTV silicone and water-tight fittings on

all wet locations connections to fixture.

1. Through one of the three NPT fittings provided, bring

in 120VAC power wiring. If 120VAC wire will not con-

veniently enter one of the three NPT fittings provided,

simply unscrew the can, rotate can 180 degrees, and

reinstall. Can is entirely symmetrical, and 180 degree

rotation will not affect mounting holes.

2. Secure wire to fixture with the appropriate strain

relief (not provided).

3. Strip 1/3” (8mm) of the insulation off each incom-

ing 120VAC power wire. Connect white incoming

120VAC wire (neutral wire) to push-in connector on

white wire from LED module. Connect black wire

from LED module. Connect ground wire to push-in

connector on green wire screwed into can. Push all

wires firmly down into connectors, so that uninsu-

lated wire is not exposed.

4. Reinstall assembly, reflector, and cover.