- 26 -

123456789012345678

123456789012345678

123456789012345678

123456789012345678

EBA 551-06

•

EBA 551-06 LT

A

B

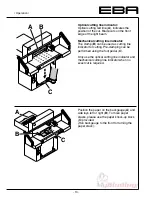

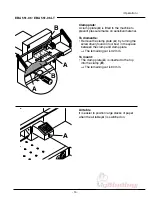

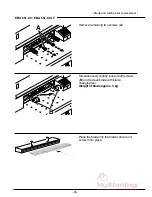

Remove remaining two screws (

A

).

Simultaneously slightly loosen both screws

(

B

) and remove blade with blade

changing tool.

Weight of blade approx. 5 kg.

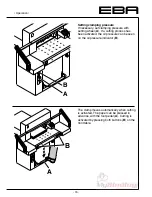

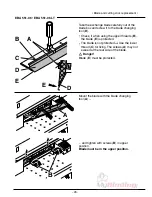

Place the blade into the blade carrier and

screw it into place.

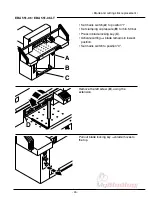

• Blade and cutting stick replacement •