3 Basic usage

VJ-1304 QUICK REFERENCE

3-30

3.8

Menu setups on the operation panel

3.8.1

Menu setup procedure

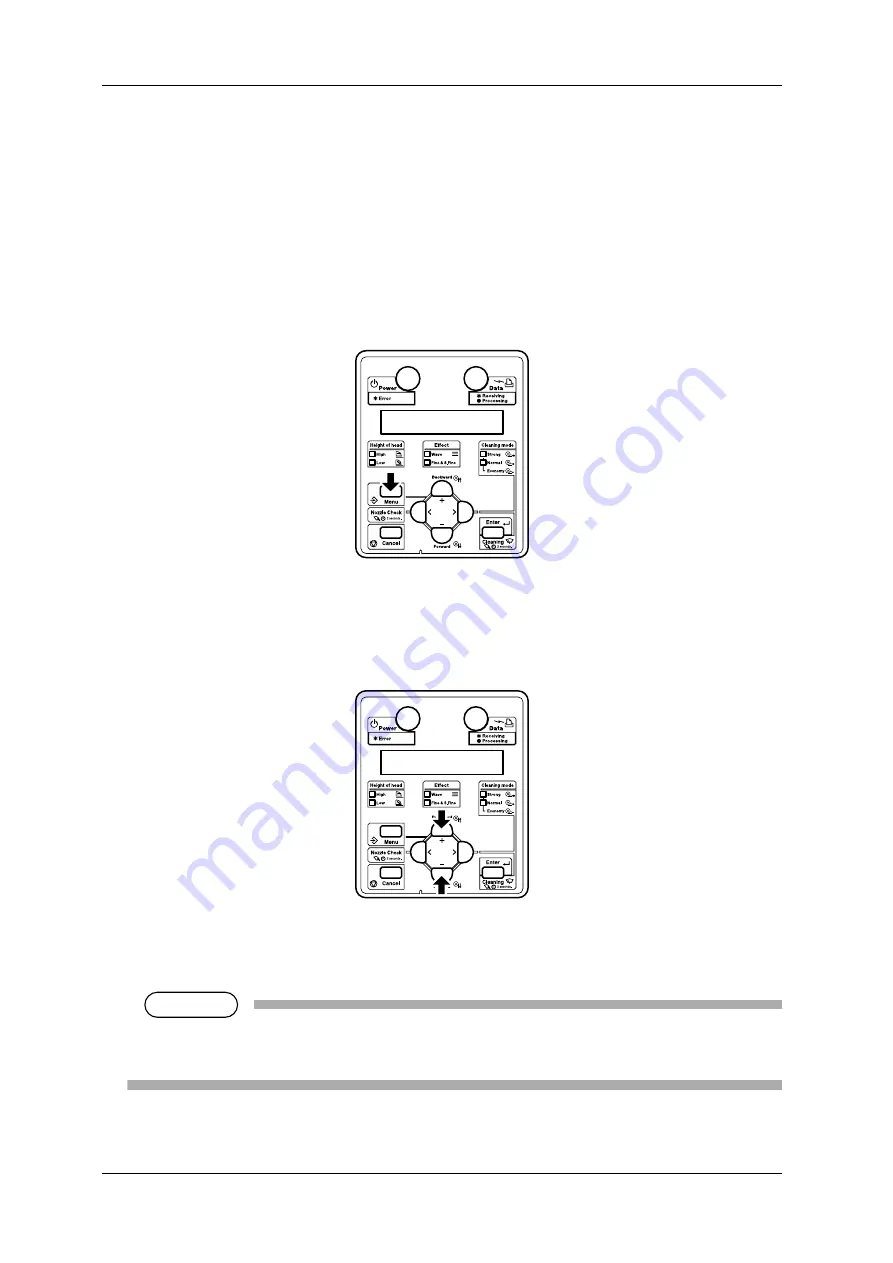

Follow the procedure below to configure each setup menu.

1. Confirm that the operation panel is Normal.

2. Press the [Menu] key on the operation panel.

•

"Menu 1: Setup>" is displayed on the operation panel.

•

The operation panel shifts to the Setup menu display.

3. Press the [+] key or [–] key on the operation panel to select a setup item and press the [Enter] key.

•

The settings will be confirmed.

•

When setup items have a submenu, the display shifts to the next menu.

NOTE

NOTE

• When a setup item has a submenu, ">" is displayed on the right end of the LCD monitor of the

operation panel.

Summary of Contents for VJ-1304

Page 1: ......

Page 2: ......

Page 18: ...1 Safety instructions VJ 1304 QUICK REFERENCE 1 10 ...

Page 78: ...4 Daily maintenance VJ 1304 QUICK REFERENCE 4 20 ...

Page 112: ...Setup menu diagram VJ 1304 QUICK REFERENCE A 6 ...

Page 113: ......

Page 114: ......