VJ-1324X OPERATION MANUAL

Panel setup menu

5.1 Setup menu

159

5.1.6.1

Ink Drying Time Menu

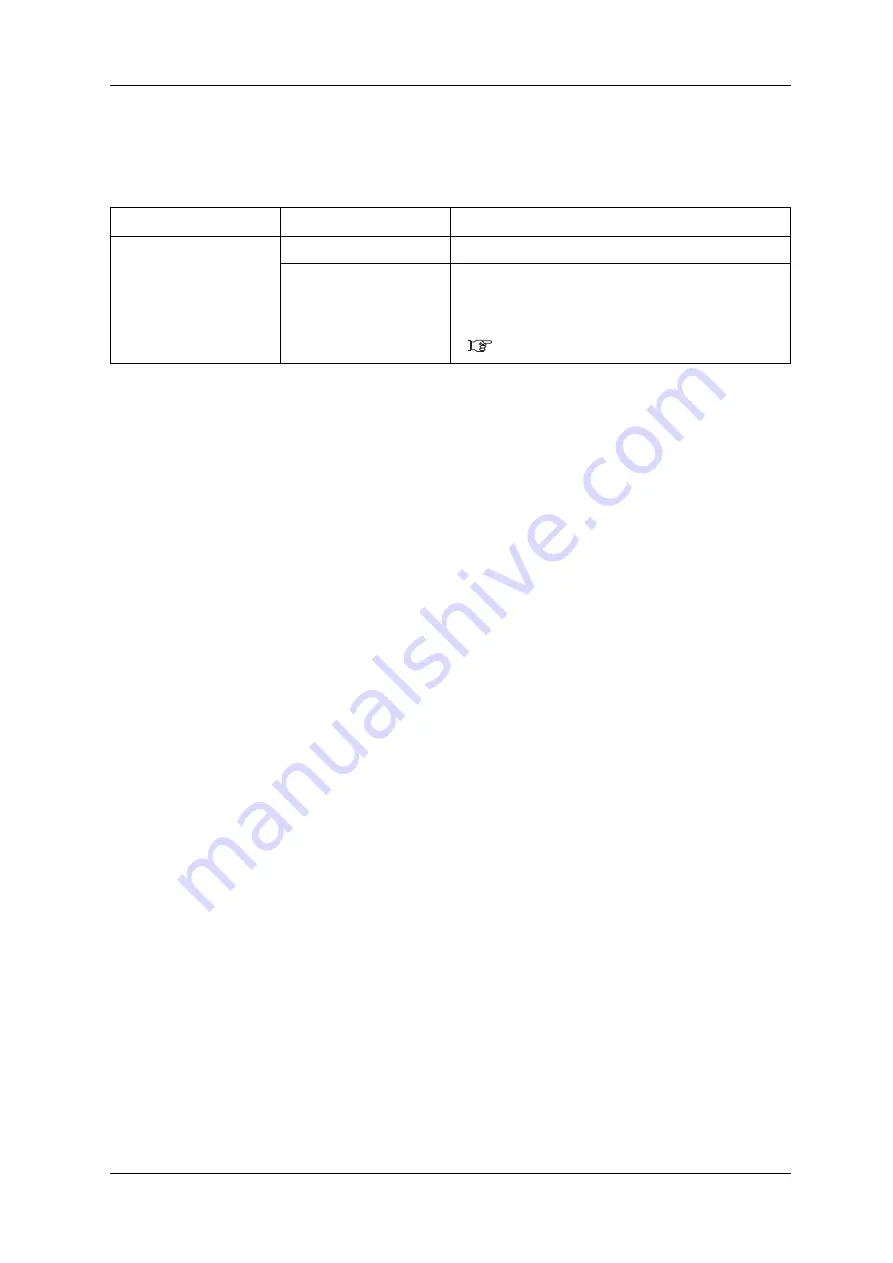

This menu is used to set ink drying time.

Setup Item

Setting

Description

Ink drying time

<0sec> to 60min

Set the ink drying time.

—

• [Enter] key: Saves the set value and shifts to the previous

menu.

• [Cancel] key: Cancels the setting and shifts to the previous

menu.

Summary of Contents for ValueJet VJ1324X

Page 1: ...VJ1324XE A 02 VJ1324X ...

Page 2: ......

Page 12: ...Table of Contents VJ 1324X OPERATION MANUAL 12 ...

Page 106: ...Before using VJ 1324X OPERATION MANUAL 106 3 7 Connecting the printer to PC ...

Page 232: ...Maintenance VJ 1324X OPERATION MANUAL 232 6 4 Moving or transporting the printer ...

Page 256: ...Appendix VJ 1324X OPERATION MANUAL 256 8 3 Options Supply list ...

Page 264: ......