20

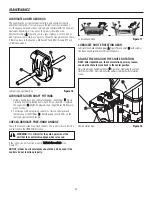

LUBRICATE AUGER GEAR BOX

The auger gear box is lubricated at the factory and should not require

additional lubrication. If for some reason the lubricant should leak out,

or if the auger gear box has been serviced, add Lubriplate GR132 Grease or

equivalent. Maximum 3- 1/4 ounces, (92 grams) should be used.

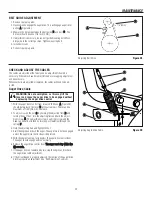

Remove filler plug (A

A, Figure 16), once a year. If grease is visible, do not

add. If grease is not visible, use a piece of fine wire, like a dipstick to check

if there is grease in the gear box. Mobilux EP1 and Shell Alvania EP1 are

suitable equivalents.

Lubricating Auger Gear Box

Figure 16

LUBRICATE AUGER SHAFT FITTINGS

1. Using a hand grease gun, lubricate the auger shaft fittings (B

B, Figure

16) every ten (10) operating hours. Each time a shear pin is replaced,

the auger shaft (C

C) MUST be greased. (See “Auger Shear Pin Replace-

ment” section.)

2. For storage or when replacing shear pins, remove shear pins and

lubricate auger shaft fittings (B

B). Rotate augers several times on the

shaft and reinstall the shear pins.

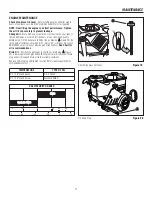

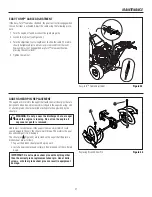

CHECK/LUBRICATE FREE-HAND LINKAGE

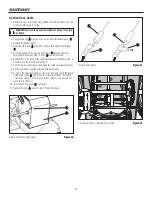

Check the function of the Free-Hand controls. The controls should function

as described in the OPERATION section.

WARNING: It is critical for the safe operation of the

unit that the controls disengage when released.

If the controls do not function properly, llubricate the controls (see

Figure 17).

NOTICE: Under no circumstances should the unit be used if the

controls do not function properly.

C

A

B

B

Lubricating Controls

Figure 17

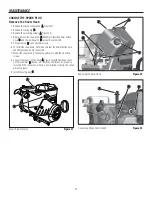

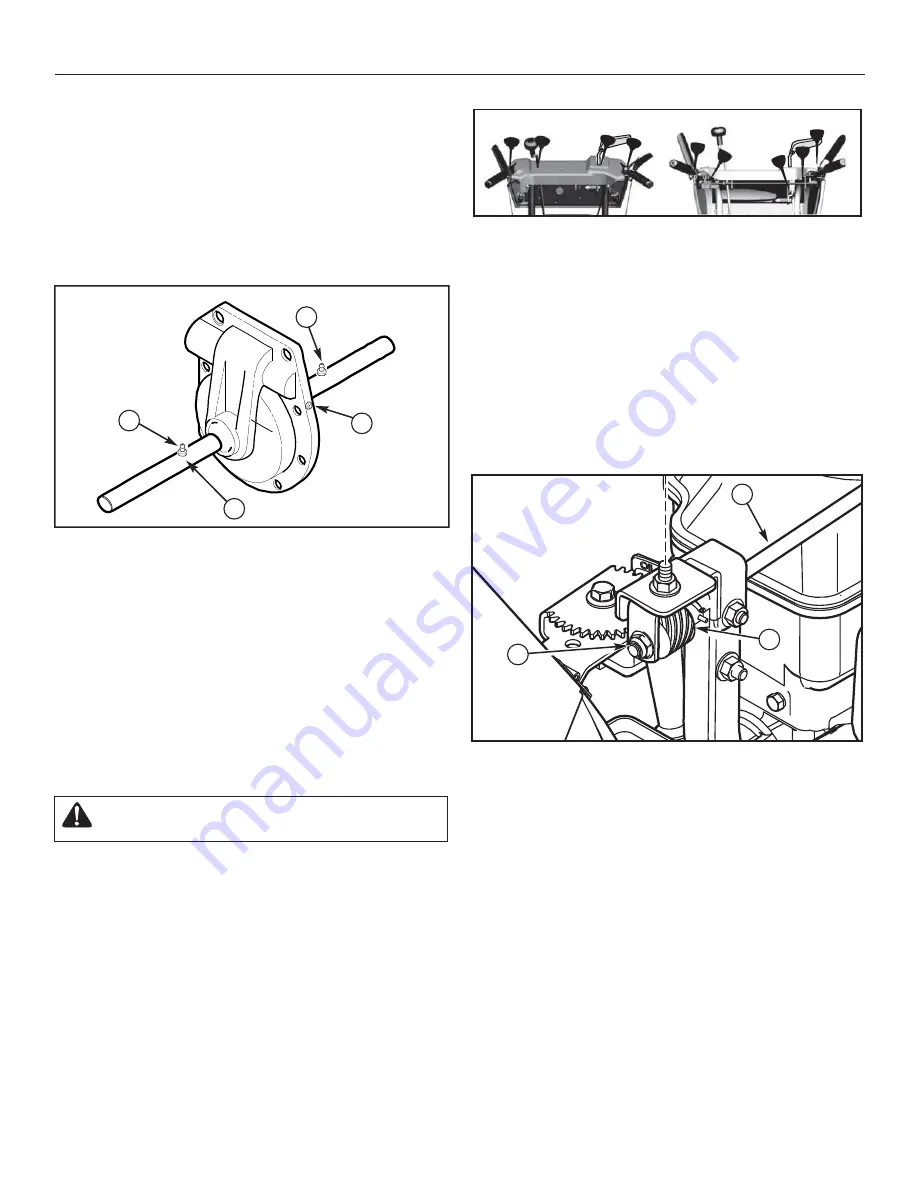

LUBRICATE CHUTE ROTATION GEAR

Lubricate the

chute rotation gear

(A

A, Figure 18) and

shaft

(B

B) with automo-

tive type oil every twenty-five (25) operating hours .

ADJUST THE DRAG ON THE CHUTE ROTATION

NOTE: After repeated use, the chute rotation gear may loosen,

causing the chute to move back to the center position.

Adjust the drag by tightening the nut (C

C, Figure 18). Tightening the nut will

limit the chute from moving without the operator turning the chute rotation

crank.

Chute Rotation Gear

Figure 18

C

A

B

MAINTENANCE