Troubleshooting

_ 97

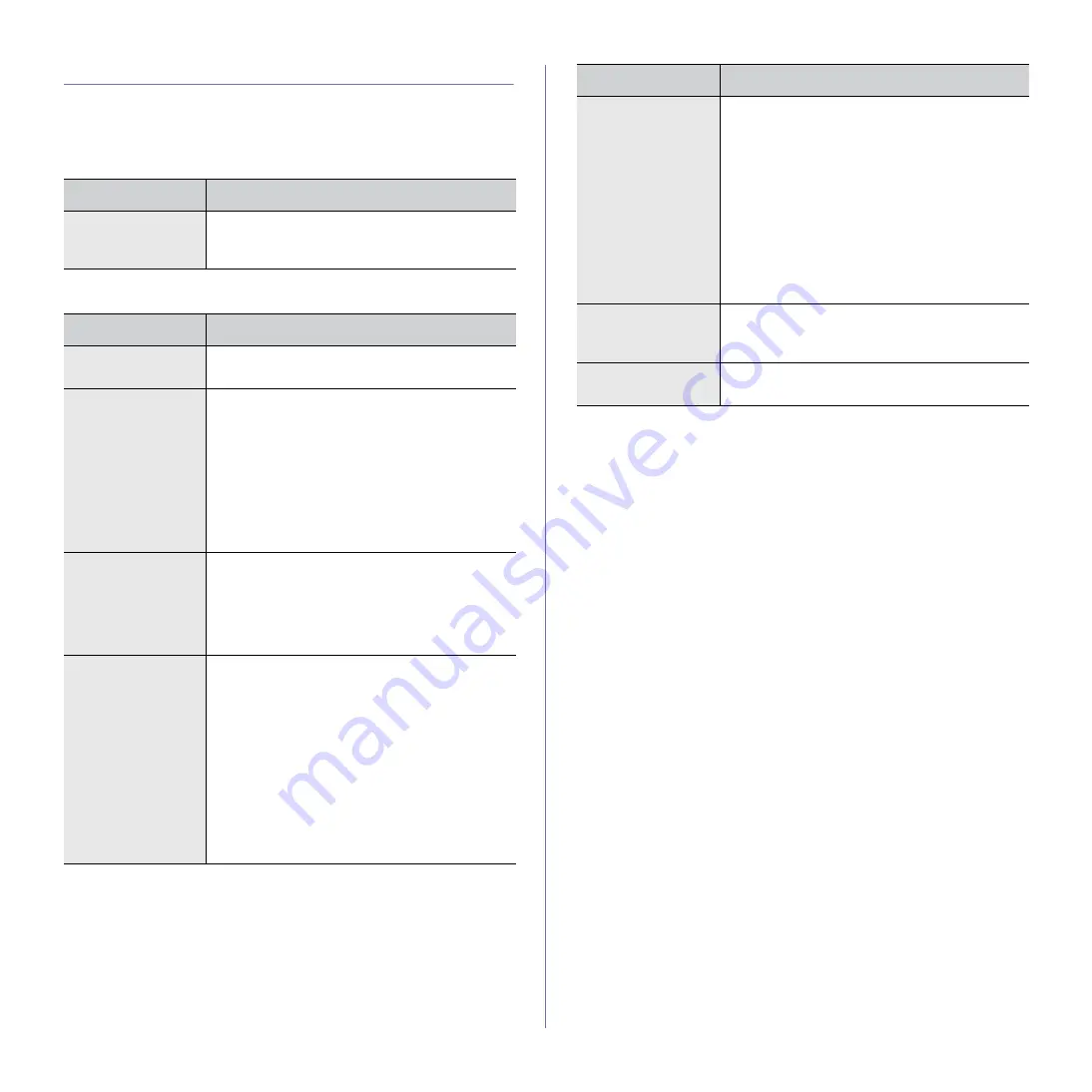

SOLVING OTHER PROBLEMS

The following chart lists some conditions that may occur and the

recommended solutions. Follow the suggested solutions until the problem is

corrected. If the problem persists, please call for service.

Touch screen problem

Paper feeding problems

CONDITION

SUGGESTED SOLUTIONS

The touch screen

does not show

anything.

Turn the machine off and turn it on again. If the

problem persists, please call for service.

CONDITION

SUGGESTED SOLUTIONS

Paper is jammed

during printing.

Clear the paper jam. (See "Clearing paper

jams" on page 88.)

Paper sticks

together.

•

Check the maximum paper capacity of the tray.

(See "Specification on print media" on

page 33.)

•

Make sure that you are using the correct type

of paper. (See "Specification on print

media" on page 33.)

•

Remove paper from the tray and flex or fan the

paper.

•

Humid conditions may cause some paper to

stick together.

Multiple sheets of

paper do not feed.

•

Different types of paper may be stacked in the

tray. Load paper of only one type, size, and

weight.

•

If multiple sheets have caused a paper jam,

clear the paper jam. (See "Clearing paper

jams" on page 88.)

Paper does not feed

into the machine.

•

Remove any obstructions from inside the

machine.

•

Paper has not been loaded correctly. Remove

paper from the tray and reload it correctly.

•

There is too much paper in the tray. Remove

excess paper from the tray.

•

The paper is too thick. Use only paper that

meets the specifications required by the

machine. (See "Specification on print

media" on page 33.)

•

If an original does not feed into the machine,

the DADF rubber pad may require to be

replaced. Contact a service representative.

The paper keeps

jamming.

•

There is too much paper in the tray. Remove

excess paper from the tray. If you are printing

on special materials, use the multi-purpose

tray.

•

An incorrect type of paper is being used. Use

only paper that meets the specifications

required by the machine. (See "Specification

on print media" on page 33.)

•

There may be debris inside the machine. Open

the front cover and remove the debris.

•

If an original does not feed into the machine,

the DADF rubber pad may need to be

replaced. Contact a service representative.

Transparencies

stick together in the

paper exit.

Use only transparencies specifically designed for

laser printers. Remove each transparency as it

exits from the machine.

Envelopes skew or

fail to feed correctly.

Ensure that the paper guides are against both

sides of the envelopes.

CONDITION

SUGGESTED SOLUTIONS

Summary of Contents for M F X - 5 5 5 5

Page 12: ...11...