The scraper and inner plate under it must be together. Set the scraper as close to

the discs as possible but ensure that the disc does not make contact with the

scraper at any point. The disc should turn freely.

3. Tighten the scraper fastening bolt.

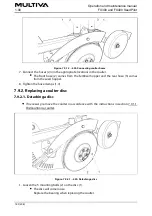

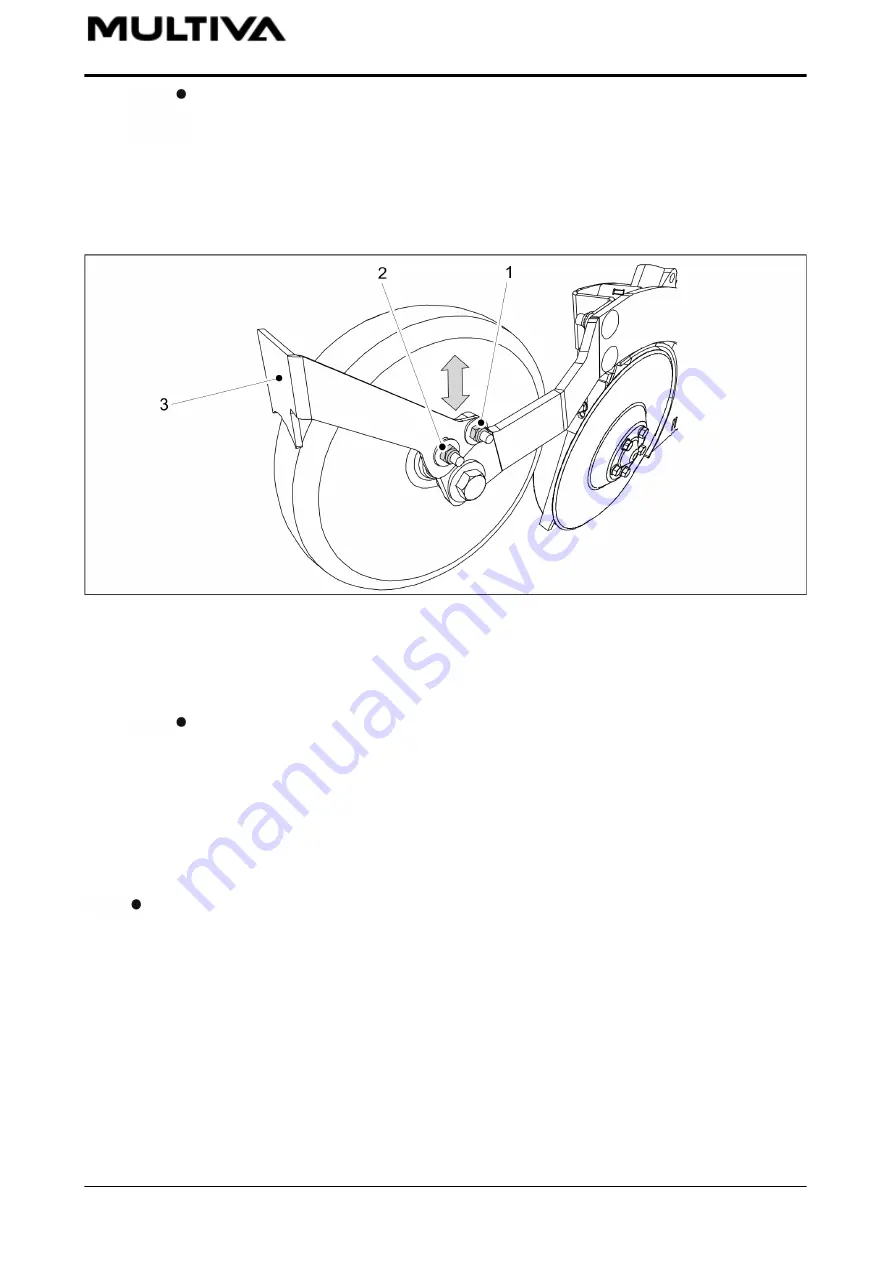

7.9.5.2. Adjusting the cover wheel scraper

Figure. 7.9.5.2. - 261. Cover wheel scraper

1. Loosen the two fastening nuts (1, 2) of the cover wheel scraper (3)

2. Adjust the distance between the scraper and the cover wheel by moving the scraper up

or down.

The distance between the scraper and the cover wheel should be 2-3 mm.

3. Tighten the scraper fastening nuts.

7.10. SeedPilot and SeedPilot ISOBUS control system

maintenance

7.10.1. Sensor calibration

The control system PIN code for sensor calibration is “3”.

7.10.1.1. Calibration of the machine seeding position sensor

1. Lower the machine to its working position.

Operation and maintenance manual

1.00

FX300 and FX400 SeedPilot

189 (208)

Summary of Contents for FX300 SeedPilot

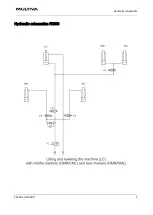

Page 200: ...Hydraulic schematics FX300 and FX400 1 Hydraulic schematics FX300...

Page 201: ...Hydraulic schematics FX300 and FX400 2...

Page 202: ...Hydraulic schematics FX300 and FX400 3 Hydraulic schematics FX400...

Page 203: ...Hydraulic schematics FX300 and FX400 4...

Page 204: ...Electrical schematics FX300 and FX400 1 Electrical schematics...