Customer Service Center

Decatur, Illinois

800.798.3131

www.muellergas.com

All warranties, expressed or implied, for Mueller Drilling Machines are

rendered null and void if the machines are used with shell cutters or

equipment manufactured by someone other than Mueller Co.

WARNING:

1. Read and follow instructions carefully. Proper training and periodic

review regarding the use of this equipment is essential to prevent possible

serious injury and/or property damage. The instructions contained

herein were developed for using this equipment on fittings of Mueller

manufacturer only, and may not be applicable for any other use.

2. Do not exceed the pressure ratings of any components or equipment.

Exceeding the rated pressure may result in serious injury and/or property

damage.

3. Safety goggles and other appropriate protective gear should be used.

Failure to do so could result in serious injury.

4. Pressure test, check for and repair leaks in all fittings and components

each time one is installed or any joint or connection is broken. Failure

to find and repair a leak from any source in the fittings, bypass lines or

equipment could result in an explosion and subsequent serious injury

and/or property damage.

5. MUELLER

®

Drilling Machines and Equipment have been carefully

designed and engineered to work together as a unit. The use of equipment

manufactured by someone other than Mueller Co. may cause excessive

wear or a malfunction of the MUELLER machines.

!

Reliable Connections

TM

Shur Stop

TM

Unit 812 PE

Line Stopping

System

8" – 12"

SDR 11 - 11.5 - 13.5

MUELLER

®

GAS

o p E R At i n G i n S t R U c t i o n S M A n U A L

TAbLE oF ConTEnTS PAGE

General Information

2

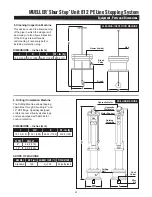

Equipment, Parts and Dimensions

3-5

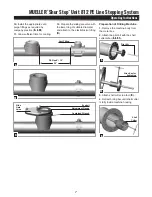

Operating Instructions

6-12

Troubleshooting and Storage

13

Notes 14-15